XCMG GR180 Grader performance characteristics: Powerful 180 HP engine, precise and efficient blade control, stable and reliable operation, comfortable driving adapted to various working conditions.

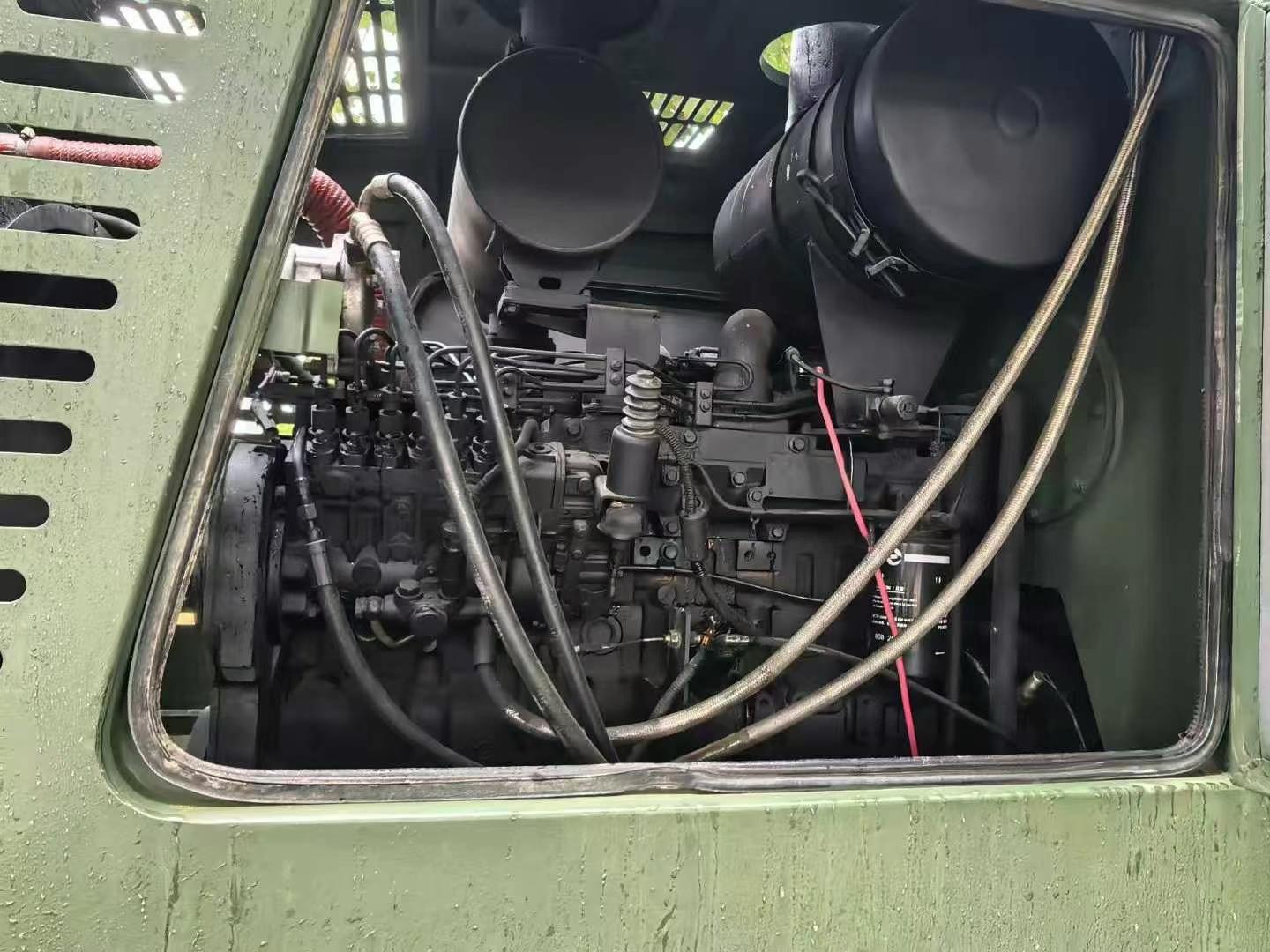

XCMG GR180 Grader (2013 model), decommissioned from a key institutional unit. Stored idle in warehouse with minimal usage. Operating hours: 220 hrs. Equipped with six brand-new tires, in quasi-new condition. Exceptionally high cost-performance ratio. Features Shanghai Diesel Engine (SDEC): 4-stroke 6-cylinder water-cooled engine, reciprocating piston internal combustion type. Capable of continuous operation exceeding 12 hours.

The XCMG GR180 Grader features a high-performance engine, delivering ample power output to meet demanding operations in complex working conditions.

Equipped with an articulated frame combined with front-wheel steering, it achieves a minimal turning radius of 7,300mm, ensuring exceptional mobility and adaptability to diverse worksites.

The electro-hydraulic control powershift transmission offers 6 forward speeds and 3 reverse speeds, catering to varied speed requirements across different operational scenarios.

The three-section drive rear axle incorporates a NO-SPIN automatic locking differential, significantly enhancing driving performance and off-road capability.

XCMG GR180 Grader Detailed Specifications

Model: GR180

Engine Model: SC8D190.2G2

Rated Power (kW): 140

Rated Speed (r/min): 2000

Min. Ground Clearance (mm): 430

Blade Lift Height (mm): 450

Blade Cut Depth (mm): 500

Blade Tilt Angle (°): 90

Blade Cutting Angle (°): 28 - 70

Blade Swing Angle (°): 360

Min. Turning Radius (mm): 7300

Max. Traction Force (kN): ≥79

Max. Gradeability (°): 20

Overall L×W×H (mm): 8900×2625×3420

Operating Weight: 15400 kg

Tire Specification: 17.5-25

Front/Rear Axle Distance (mm): 6219

Center-to-Rear Axle Distance (mm): 1538

Wheel Track (mm): 2156

Blade Length×Height (mm): 3965×610

Daily Maintenance for Motor Grader

1. Fluid Level Check: Check engine oil, hydraulic oil, and coolant levels daily; replenish promptly. Replace hydraulic oil every 250 hours.

2. Cleaning Maintenance: Clean mud from the machine body after operation; focus on cleaning the radiator and air filter. Check tire pressure and blade wear.

3. Lubrication Maintenance: Apply lithium-based grease daily to moving parts like blade hinges and bearings.

4. Function Test: Check lights, brakes, and hydraulic system response before startup; observe dashboard warning lights after operation.

5. Safety & Records: Shut down and disconnect power during maintenance; record operation logs (anomalies, fuel consumption). Increase cleaning/lubrication frequency in harsh environments.

Core Objective: Prevent failures, extend service life, ensure operational safety.