The XCMG GR215 Motor Grader is mainly used for ground leveling of large areas such as highways, airports, farmland, etc., as well as for operations like trenching, slope cutting, bulldozing, scarifying, and snow removal

A certain organization is decommissioning an XCMG GR215 Motor Grader with 880 hours of operation. As part of the organization's supporting machinery, despite its relatively low usage due to the organization's specific nature, it has undergone scheduled maintenance strictly according to internal regulations. Consequently, although manufactured a decade ago, this machine remains in exceptionally good condition! Offering the performance of a new vehicle at the price of a used one, it delivers exceptional cost-effectiveness!

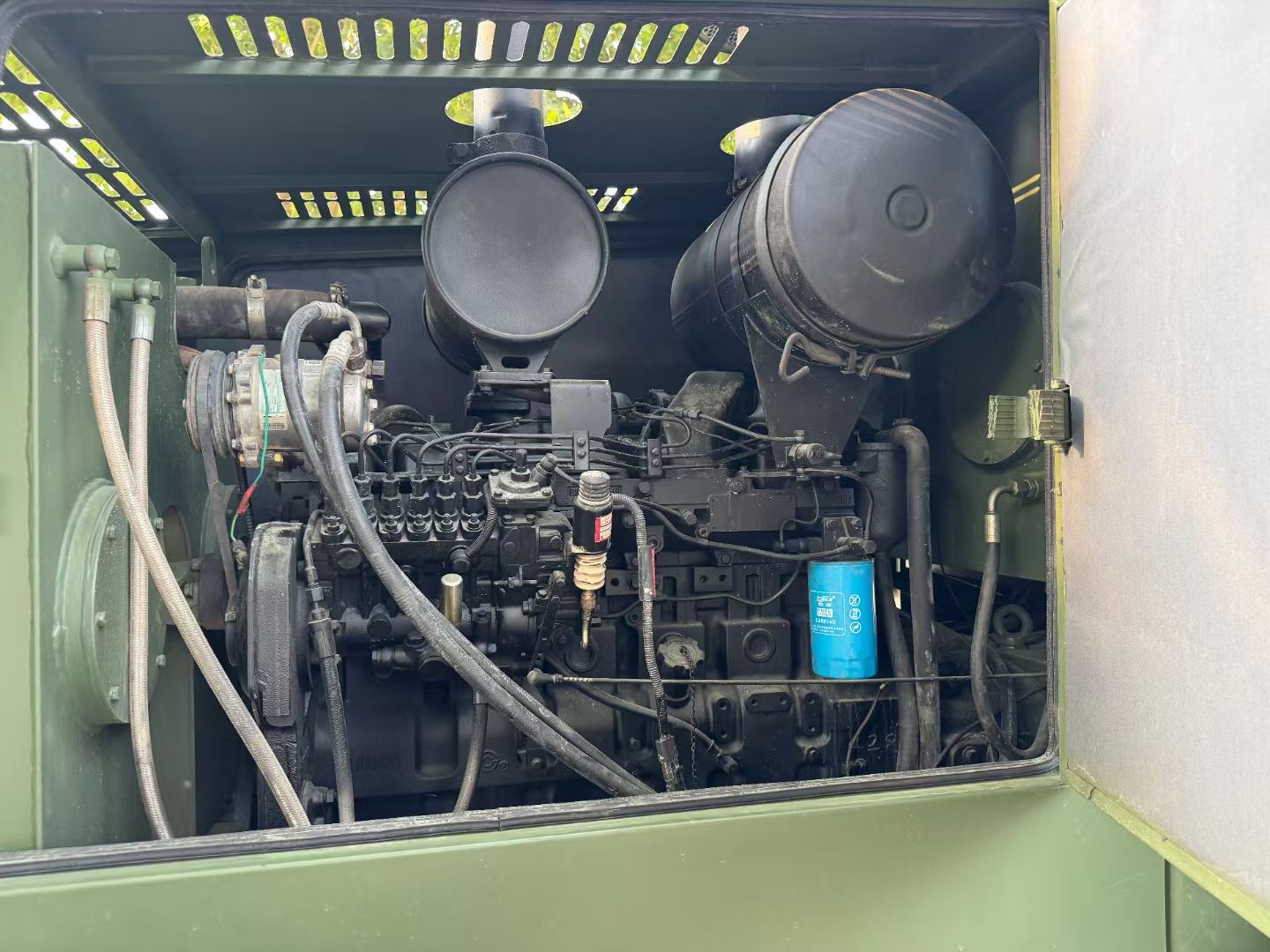

Originating from decommissioned equipment of a military unit, this machine undergoes rigorous maintenance adhering to military-grade standards, ensuring stable and reliable performance. The body structure utilizes high-strength alloy materials for exceptional durability and adaptability to complex working conditions. Equipped with an original imported hydraulic system, it delivers powerful performance with operational accuracy reaching ±3mm. Leveling efficiency surpasses conventional equipment by 30%, enabling immediate project deployment upon delivery. Compared to new machinery, it reduces procurement costs by 60%, making it ideal for roadbed construction, site leveling, mine stripping, and similar engineering applications. Particularly suited for small-to-medium construction enterprises seeking cost-effective efficiency enhancement solutions.

Detailed Specifications of XCMG GR215 Motor Grader

Model: GR215

Engine Model | Dongfeng Cummins: 6CTA8.3

Rated Power (kW): 160

Rated Speed (r/min): 2200

Hydraulic System Rated Working Pressure (MPa): 18

Wheelbase (mm): 2156

Blade Lift Height (mm): 28 - 70

Blade Cutting Depth (mm): 360

Maximum Gradeability (°): ≥25

Operating Hours: 880 hours

Overall Dimensions (mm): 8970 × 2625 × 3470

Operating Weight: 16500 kg

Minimum Turning Radius (mm): 90000

Tire Specification: 17.5 - 25

Daily Maintenance for Motor Grader

1. Fluid Level Check: Check engine oil, hydraulic oil, and coolant levels daily; replenish promptly. Replace hydraulic oil every 250 hours.

2. Cleaning Maintenance: Clean mud from the machine body after operation; focus on cleaning the radiator and air filter. Check tire pressure and blade wear.

3. Lubrication Maintenance: Apply lithium-based grease daily to moving parts like blade hinges and bearings.

4. Function Test: Check lights, brakes, and hydraulic system response before startup; observe dashboard warning lights after operation.

5. Safety & Records: Shut down and disconnect power during maintenance; record operation logs (anomalies, fuel consumption). Increase cleaning/lubrication frequency in harsh environments.

Core Objective: Prevent failures, extend service life, ensure operational safety.