The TIANGONG TG180 Motor Grader delivers powerful 180HP performance, with precise and stable hydraulic controls. It adapts flexibly and efficiently to complex terrain, making it ideal for medium-scale projects while offering superior overall cost-effectiveness

A 2011 TIANGONG TG180 Motor Grader retired from a government unit. As supporting equipment for the organization, it saw minimal usage—predominantly stored indoors throughout its service period. With only 267 hours of operation over 13 years, this Cummins-powered machine features six 95%-new tires and exhibits responsive hydraulic operations, presenting in near-new condition

The TIANGONG TG180 Motor Grader is equipped with a 210HP diesel engine delivering robust and reliable power, featuring high fuel efficiency while complying with China III emission standards. Its hydraulic control system ensures precision and stability, supporting all-wheel steering for agile adaptation to complex terrains such as rugged construction sites or confined spaces.

The rugged frame design guarantees exceptional durability and operational efficiency, making it ideally suited for medium-scale projects including road construction, subgrade shaping, and site leveling. With superior overall cost-effectiveness, straightforward maintenance, and proven performance, it remains a*top-tier choice for earthmoving operations

Tiangong TG180 Motor Grader Detailed Specifications

Model: Tiangong TG180

Year of Production: 2011

Engine Model: Cummins QSB6.7

Engine Type: In-line 6-cylinder, turbocharged, water-cooled diesel

Rated Power/Speed: 157 kW / 210 HP

Max. Torque: ≥ 950 N·m @ 1500 rpm

Fuel Tank Capacity: 280 L

Operating Weight: Approx. 16,800 kg

Transport Configuration: Approx. 8.98 m × 2.55 m × 3.35 m

Min. Turning Radius: ≤ 8.5 m

Max. Cutting Depth: 500 mm

Max. Lift Height: 450 mm

Side Shift Range: 850 mm (both sides)

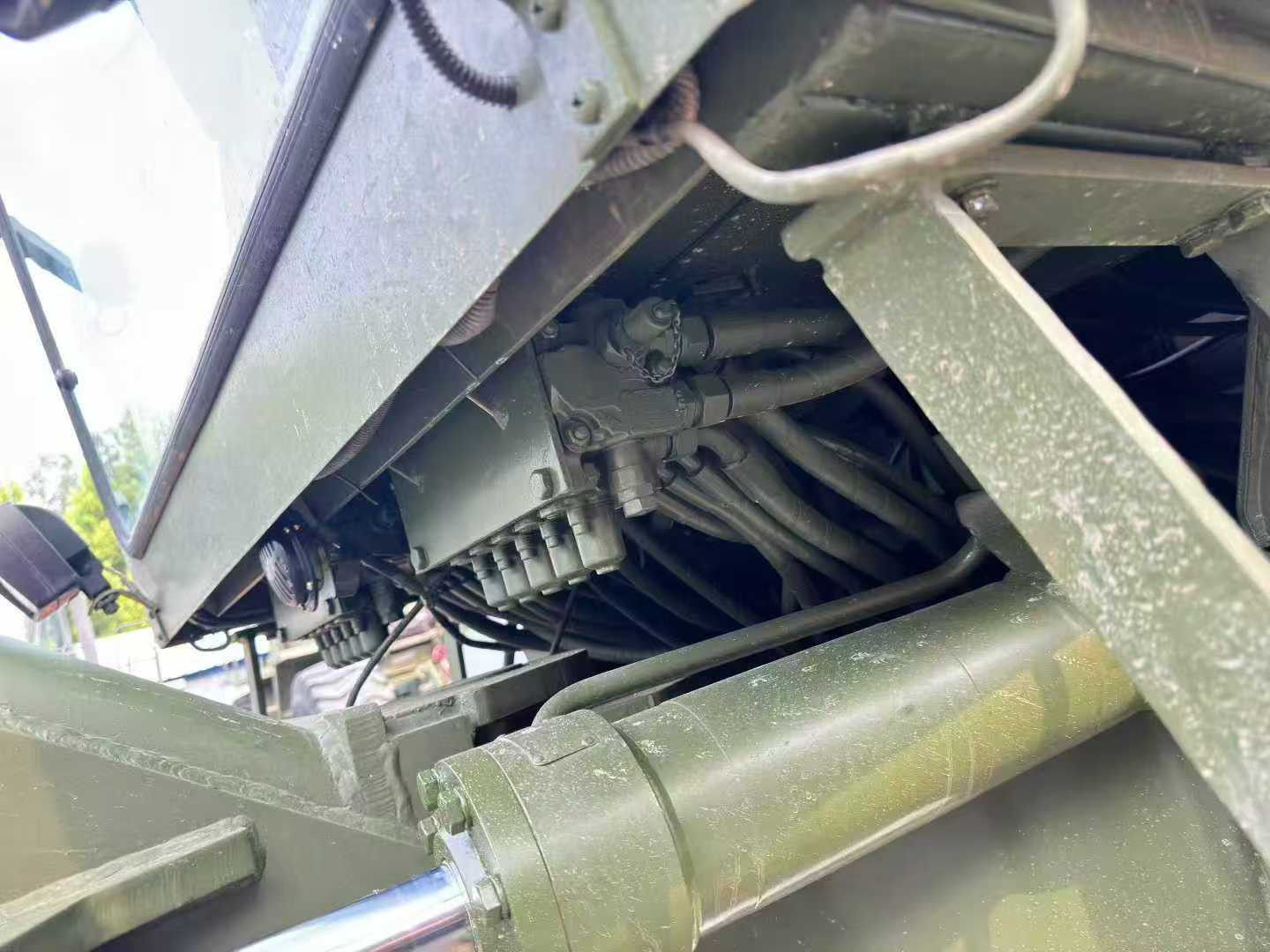

Detail Picture

Daily Maintenance for Motor Grader

1. Fluid Level Check: Check engine oil, hydraulic oil, and coolant levels daily; replenish promptly. Replace hydraulic oil every 250 hours.

2. Cleaning Maintenance: Clean mud from the machine body after operation; focus on cleaning the radiator and air filter. Check tire pressure and blade wear.

3. Lubrication Maintenance: Apply lithium-based grease daily to moving parts like blade hinges and bearings.

4. Function Test: Check lights, brakes, and hydraulic system response before startup; observe dashboard warning lights after operation.

5. Safety & Records: Shut down and disconnect power during maintenance; record operation logs (anomalies, fuel consumption). Increase cleaning/lubrication frequency in harsh environments.

Core Objective: Prevent failures, extend service life, ensure operational safety.