Motor graders are primarily used for highway subgrade shaping, site fine grading, farmland water conservancy improvement, snow maintenance, and mine working face leveling—all scenarios requiring high ground flatness precision

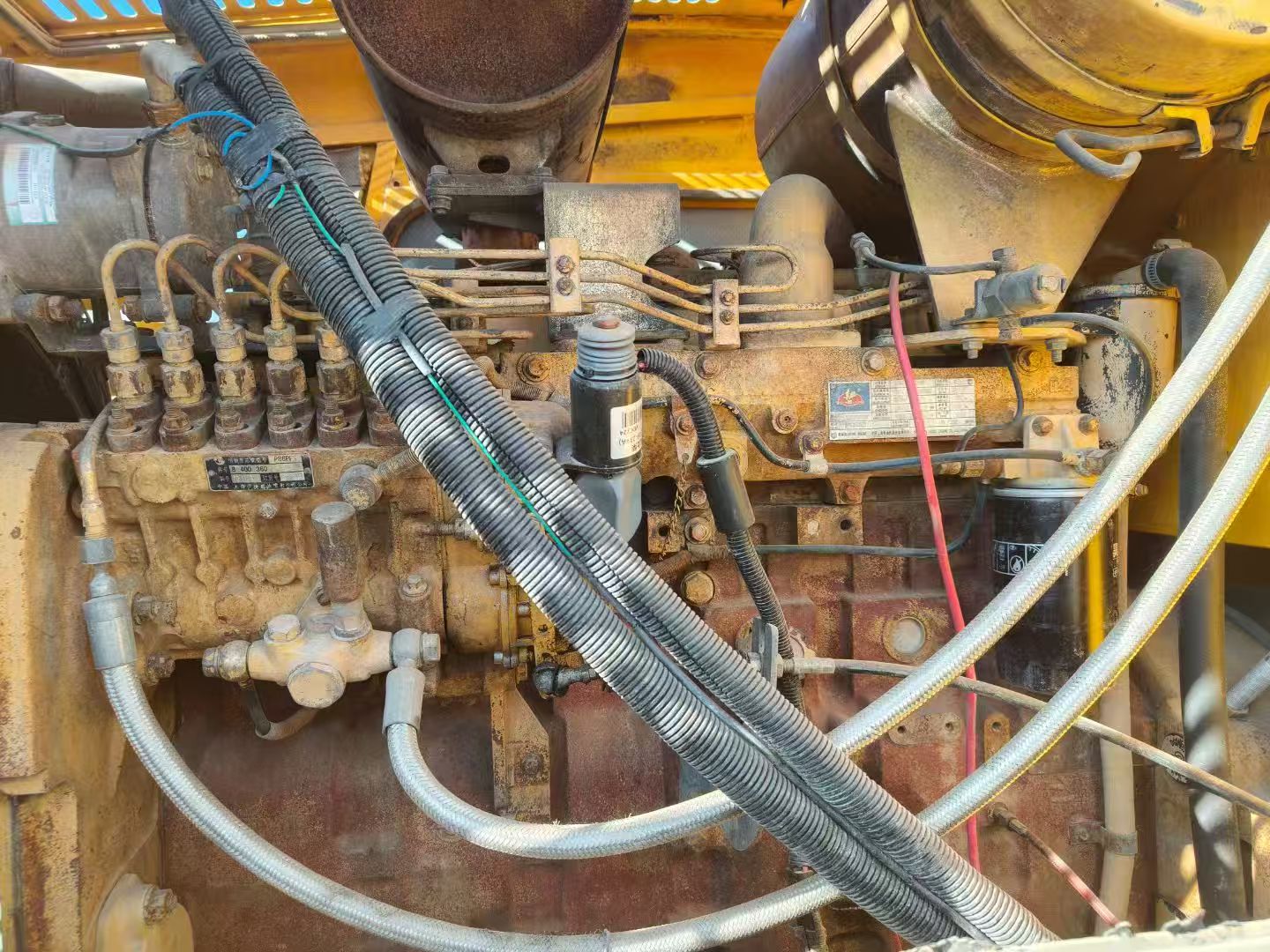

A performance-proven motor grader manufactured in 2010 with 6,500 operating hours. Maintained with regular servicing during use, featuring smooth cold starts, stable idle operation without abnormal noises, excellent hydraulic system performance, and highly cost-effective pricing

The XCMG GR180 motor grader is equipped with a 160kW Weichai engine. Its 6×4 all-wheel drive system enables stable operation on 20° slopes, with a maximum travel speed of 39 km/h. The 3.66-meter blade achieves 540mm cutting depth, while ±850mm hydraulic side-shift and 360° continuous rotation functions work in synergy to deliver millimeter-level grading precision for subgrade projects. The 25mm reinforced frame structure effectively withstands impact loads. Suitable for diverse applications including highway subgrade fine-grading, mine site compaction, frozen soil treatment, and farmland rehabilitation, its 16.5-ton operating weight balances efficiency and stability.

XCMG GR180 Motor Grader Detailed Specifications

Model: GR180

Type: Hydraulic-mechanical motor grader

Drive configuration: 6×4 all-wheel drive

Engine model: Weichai WD10G220E21

Rated power: 160kW (218 hp) @ 2,200 rpm

Fuel tank capacity: 300L

Operating weight: 16,500 kg

Blade length: 3,660 mm

Max blade lift height: 520 mm

Max cutting depth: 540 mm

Front bulldozer plate width: 2,900 mm

Overall dimensions: 8,980 × 2,470 × 3,350 mm

Wheelbase: 6,200 mm

Min turning radius: 7.8 m

Transmission: Fixed-shaft power shift transmission (6 forward / 3 reverse gears)

Daily Maintenance for Motor Grader

1. Fluid Level Check: Check engine oil, hydraulic oil, and coolant levels daily; replenish promptly. Replace hydraulic oil every 250 hours.

2. Cleaning Maintenance: Clean mud from the machine body after operation; focus on cleaning the radiator and air filter. Check tire pressure and blade wear.

3. Lubrication Maintenance: Apply lithium-based grease daily to moving parts like blade hinges and bearings.

4. Function Test: Check lights, brakes, and hydraulic system response before startup; observe dashboard warning lights after operation.

5. Safety & Records: Shut down and disconnect power during maintenance; record operation logs (anomalies, fuel consumption). Increase cleaning/lubrication frequency in harsh environments.

Core Objective: Prevent failures, extend service life, ensure operational safety.