A motor grader is an engineering machine used for road construction, accomplishing tasks such as ground leveling, slope trimming, and trench excavation through its long frame equipped with a blade and wheeled chassis

2014 Decommissioned TIANGONG PG180 Motor Grader – Exceptional Value

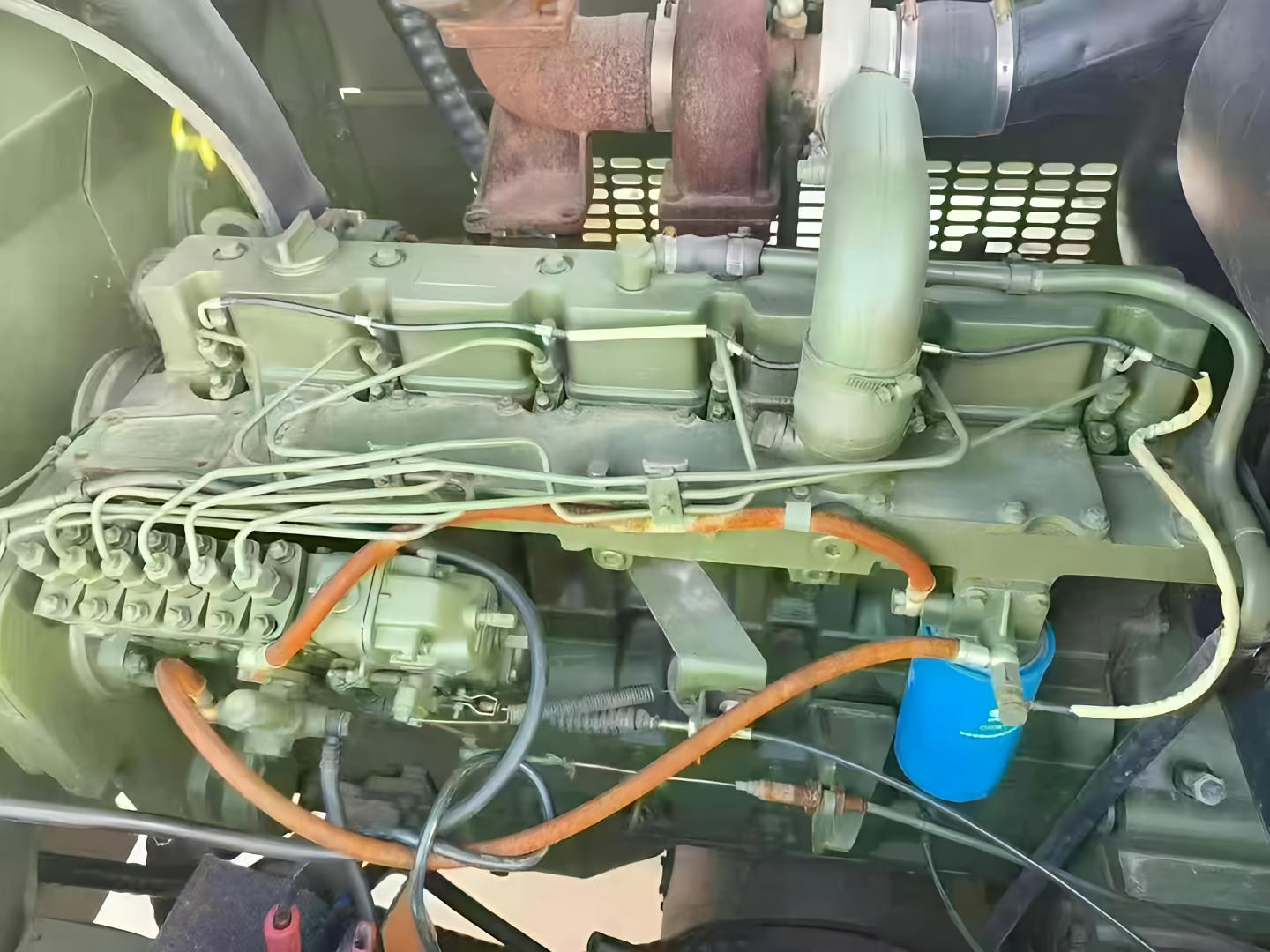

Tires 90% new, main blade unused; hydraulic system in perfect condition, equipped with Shangchai SC9DK280G3 engine (performance comparable to new machines); automatic transmission control, 3.96-meter ultra-wide blade, four-wheel disc brakes for enhanced safety. Decommissioned unit equipment, rugged working condition, significant price advantage.

Decommissioned Military Motor Graders Export Special – Forged by Military DNA for Ultimate Reliability

I. Military-Grade Quality: Rigorous Standards Create Extraordinary Performance

1. Exceptional Durability

Military equipment strictly follows full lifecycle management. Each machine comes with complete maintenance records.

Key components (engine, hydraulic system) have accumulated only 10%-30% of the operating hours typical for civilian equipment of the same age. Wear levels are far below market averages.

Mandatory periodic overhaul: ≥2 comprehensive disassembly maintenance sessions annually, ensuring core component condition approaches factory-new standards.

2.Extreme Condition Adaptability

Proven in live-fire training grounds, plateau/extreme-cold environments, and other harsh conditions.

Equipment reliability increased by ≈40% (compared to failure rate statistics of equivalent civilian models), making it especially suitable for high-pressure scenarios like mines and energy infrastructure construction.

3. Zero Aftermarket Modification Risks

Unlike civilian refurbished machines which may have non-standard parts or modifications, decommissioned military equipment uses only original factory parts throughout its service life.

Zero third-party technical intervention eliminates compatibility hazards.

TIANGONG PG180 Motor Grader Detailed Specifications

Model: Tiangong PG180

Engine: Shangchai SC9DK280G3

Rated Power: 209 kW/280 HP (2200 rpm)

Max Torque: 1100 N·m (1400-1600 rpm)

Fuel Tank Capacity: 400 L

Blade Width: 4 m

Max Blade Lift Height: 580 mm

Blade Side Shift Range: ±850 mm

Blade Cutting Angle Adjustment: 45°–70°

Max Traction Force: 180 kN

Max Travel Speed: 39 km/h

Min Turning Radius: 8.5 m

Gradeability: 30°

Transmission Type: Hydro-mechanical transmission, ZF 6WG180 gearbox (6 forward / 3 reverse gears)

Hydraulic Pump Flow: Main pump 260 L/min (rated pressure 21 MPa)

Steering System: Full hydraulic articulated steering, steering angle ±25°

Brake System: Oil-over-air four-wheel disc brakes with ABS

Operating Weight: 16.8 t

Wheelbase: 6.2 m

Tire Specification: 14.00-24-28 PR

Ground Clearance: 380 mm

Cab Height: 2.1 m (foldable ROPS/FOPS)

Daily Maintenance for Motor Grader

1. Fluid Level Check: Check engine oil, hydraulic oil, and coolant levels daily; replenish promptly. Replace hydraulic oil every 250 hours.

2. Cleaning Maintenance: Clean mud from the machine body after operation; focus on cleaning the radiator and air filter. Check tire pressure and blade wear.

3. Lubrication Maintenance: Apply lithium-based grease daily to moving parts like blade hinges and bearings.

4. Function Test: Check lights, brakes, and hydraulic system response before startup; observe dashboard warning lights after operation.

5. Safety & Records: Shut down and disconnect power during maintenance; record operation logs (anomalies, fuel consumption). Increase cleaning/lubrication frequency in harsh environments.

Core Objective: Prevent failures, extend service life, ensure operational safety.