A loader is a self-propelled piece of earthwork machinery capable of performing tasks such as scooping, loading, transporting and unloading.

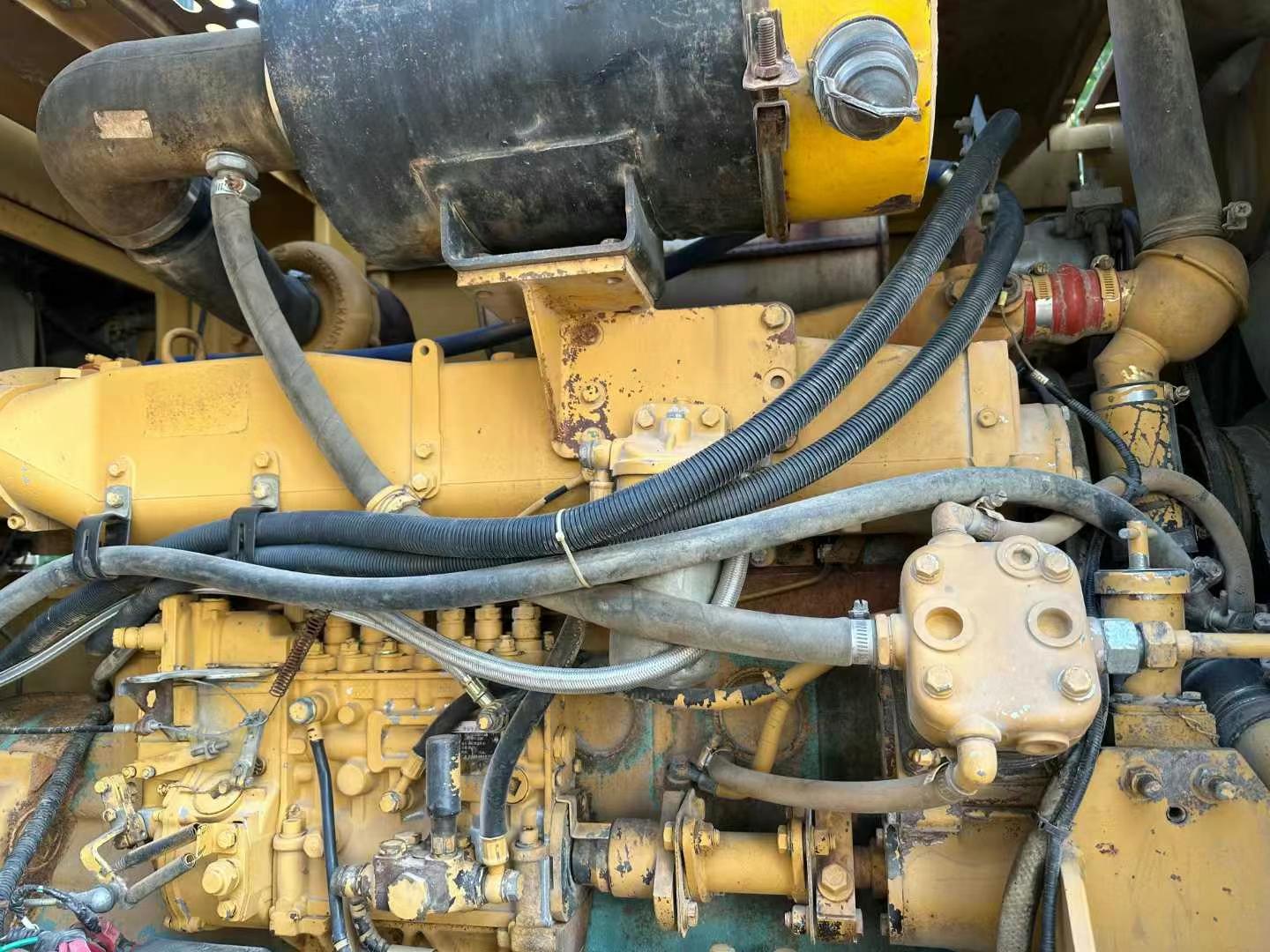

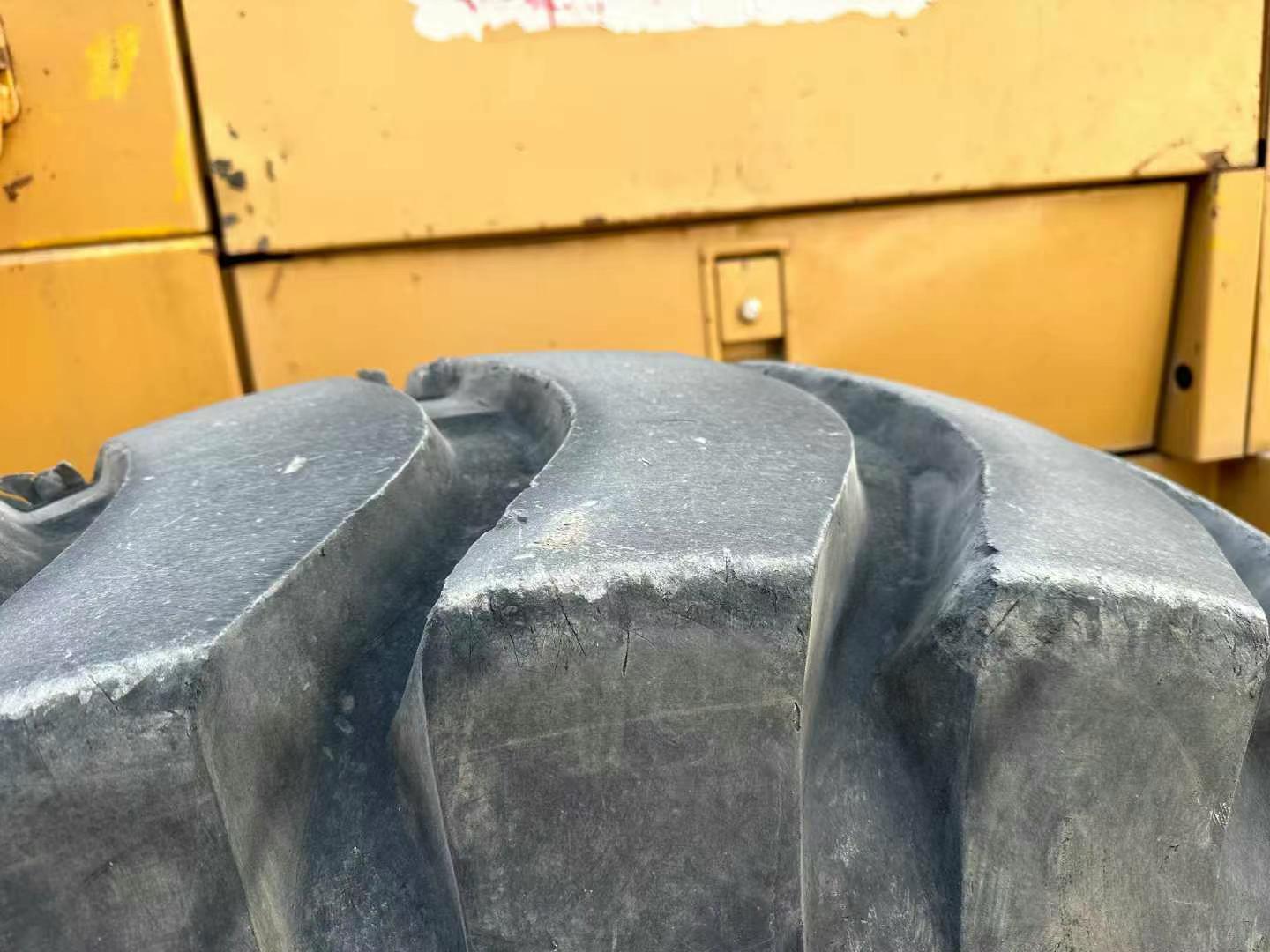

The 2014 Liugong ZL50D loader, although its appearance seems a bit outdated, its operational duration is only 1600 hours. This is a loader that was phased out by a state-owned enterprise. By looking at the pictures of its tire wear and other details, one can conclude that it is an extremely excellent machine. After our engineers' subsequent processing, it will become as good as a new one!

Performance Parameters

Engine model: Wucheng WD615

Rated power: 158 kW / 2200 rpm

Fuel tank capacity: 300 L

Rated load capacity: 5 tons

Maximum lifting force: 167 kN

Overall working weight of the machine: 16,500 kg

Minimum turning radius on the outside: 6,750 mm

Performance Features

The Liugong ZL50D loader is equipped with a high-power engine, providing strong power output and enabling it to complete various loading operations quickly and efficiently. It has a large loading capacity and a high unloading height, allowing for the simultaneous loading of more materials and improving work efficiency. The stable working platform design ensures good anti-overturning performance, enabling it to work smoothly on uneven terrain. It is equipped with an advanced hydraulic system and control system, which is flexible, smooth to operate, and easy to use, and can adapt to various working environments and operational requirements. High-quality materials and components are used, featuring durability, allowing it to operate stably under long-term, heavy-load working conditions. Maintenance and servicing are relatively simple and convenient, with readily available components and relatively low maintenance costs.

Maintenance And Care

As an indispensable piece of machinery in construction projects, loaders are crucial for the progress of the projects. Regular maintenance and care of the loaders can not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine. If necessary, perform maintenance or replace components;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.