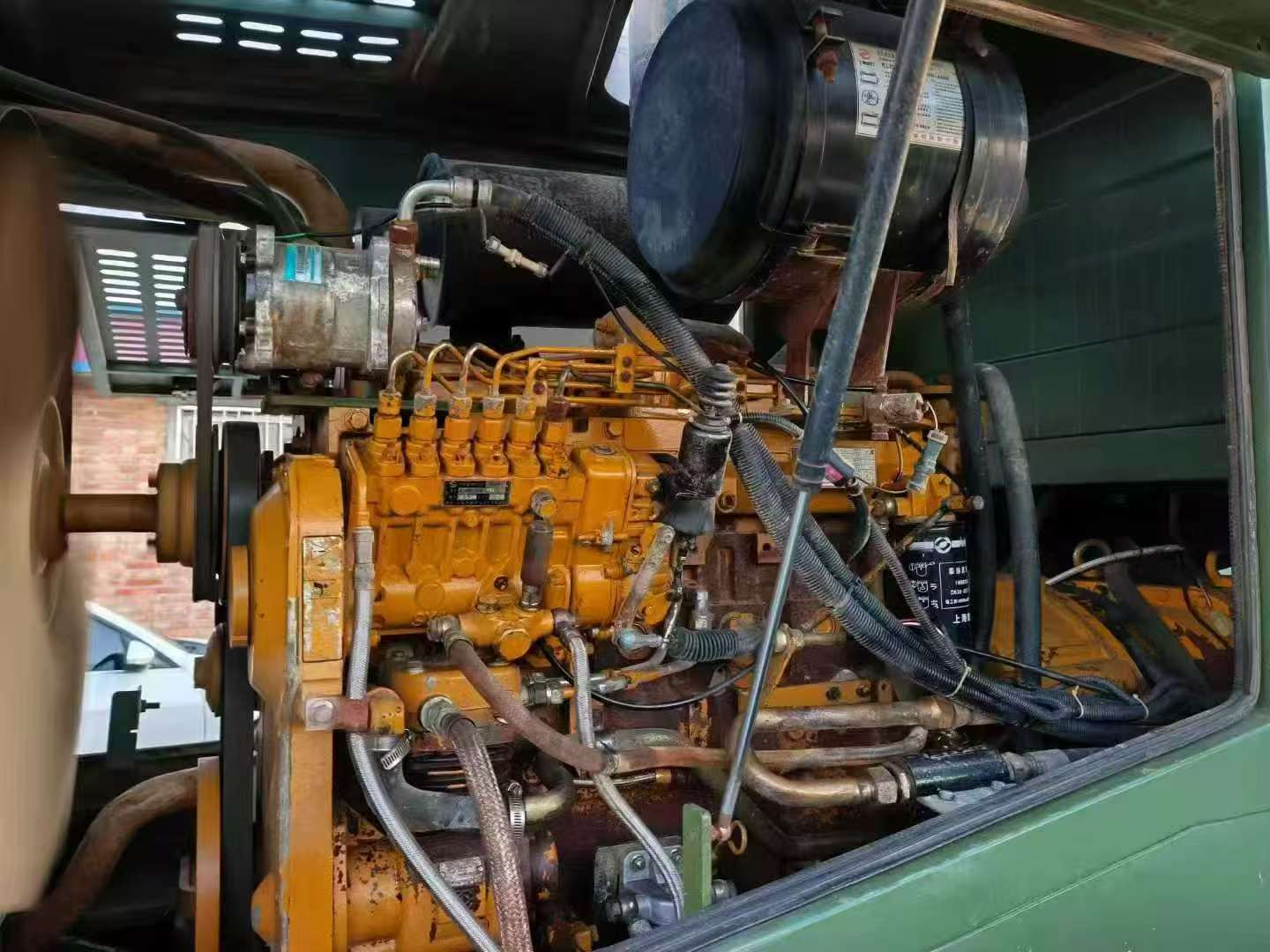

WEICHAI POWER delivers robust and reliable engine performance, rapid and smooth hydraulic response, and exceptional overall durability. Designed for efficient mining and port operations, it is specifically suited for heavy-duty bulk material handling tasks under demanding conditions.

This authentic factory-configured unit records only 2,000 operational hours. WEICHAI POWER delivers robust and stable performance with rapid hydraulic response, operating like new. The pristine cabin shows zero wear, complemented by four original tires ensuring extended durability. Its exceptional condition stems from regulated departmental usage: exclusively deployed for base infrastructure development and training support with minimal task intensity. Maintained under stringent protocols including designated maintenance facilities, uniform fuel specifications, and strict overload prevention. A rare industry-recognized gem among decommissioned equipment, performing at near-new levels while offering unbeatable value proposition for efficient project execution.

Throughout our export operations, we adhere to one core principle: Quality is non-negotiable, while price remains secondary. While competitors may race to the bottom with cutthroat pricing, we know knowledgeable customers recognize that durability and safety define true value. A foundationally sound loader, expertly refurbished to minimize failures and extend service life, delivers genuine long-term savings. We reject superficial shine masking mechanical flaws,such machines only cause operational headaches abroad. Our story is simple: Meticulous selection, precision refurbishment, and heartfelt dispatch across oceans. We transform equipment into trusted partners for our clients' success.

XCMG LW400K Technical Specifications

Engine Model: SC9DK280Q3

Rated Power: 162 kW @2200 rpm

Max Torque: 860 N·m @1400-1600 rpm

Fuel Tank Capacity: 300 L

Transmission: ZF Fixed-Shaft Electro-Hydraulic Power Shift Transmission

Drive Axle: XCMG Self-Developed Heavy-Duty Drive Axle with Limited-Slip Differential

Top Speed: 38 km/h

Rated Load Capacity: 4.0 tons

Standard Bucket Capacity: 2.2-2.5 m³

Max Digging Force: ≥160 kN

Max Traction Force: 145 kN

Dumping Height: 3050 mm

Operating Weight: 14.8 tons

Dimensions (L×W×H): 8150×2980×3450 mm

Maintenance And Care

As an indispensable mechanical equipment in construction projects, the efficient and stable operation of loaders is crucial for the progress of the project. Regular maintenance and care of loaders can not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine. If necessary, perform maintenance or replace components;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.