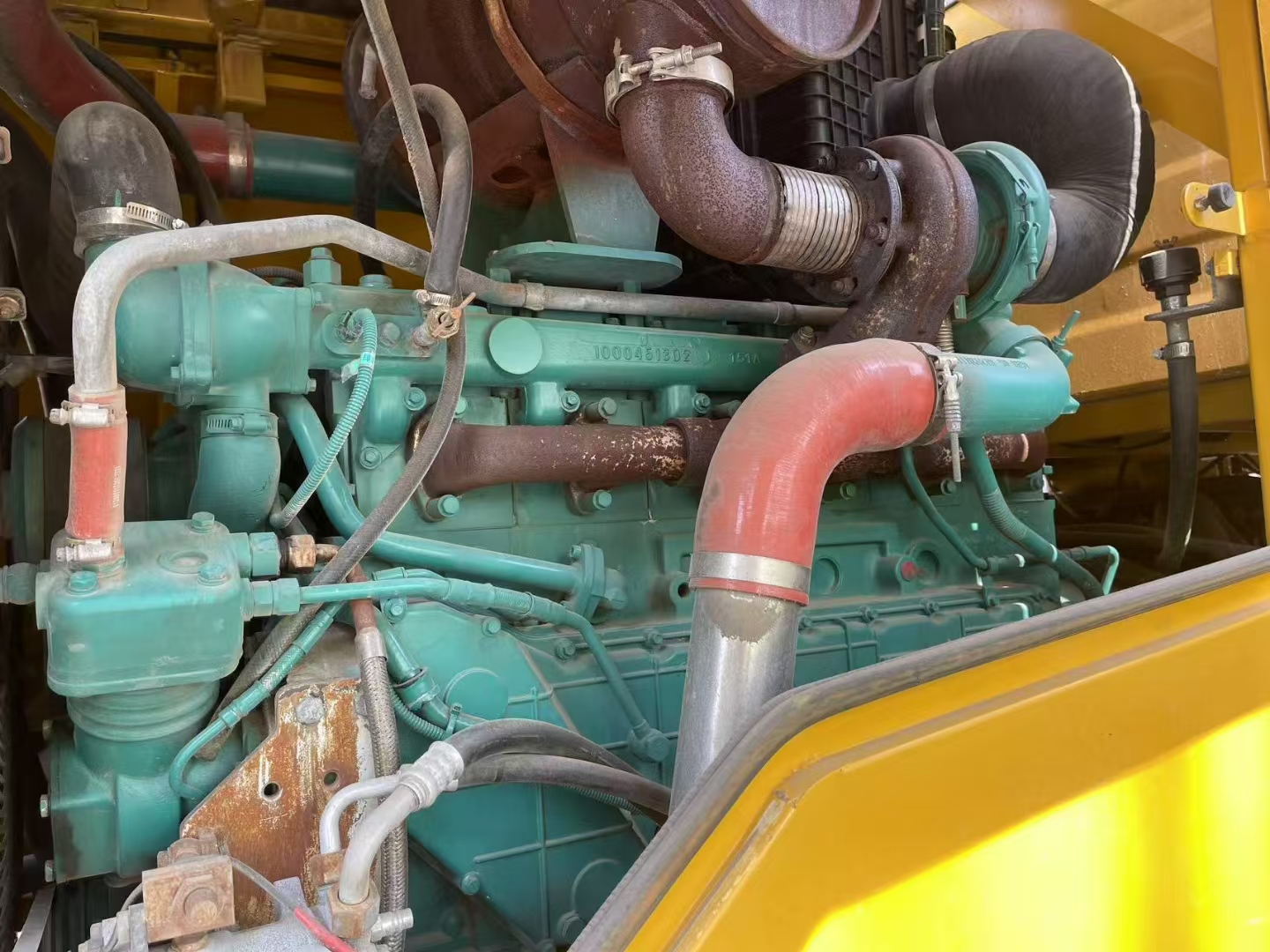

The Lingong 955F loader adopts a low-speed energy-saving National III electronic fuel injection Weichai engine with a fault detection interface.

This is a 2021 LinGong L955F wheel loader with excellent condition. The whole vehicle adopts a brand-new streamlined appearance design, making the overall shape aesthetically pleasing. The new-generation cab is newly optimized based on ergonomics, with a 15% increase in space, ensuring safety and comfort. The digital step-by-step instrument display has high human-machine interaction. The entire electrical system is centrally controlled, making detection and maintenance convenient. It uses 18-level tires, which are more suitable for harsh working conditions.

About Wheel Loader Lingong 955

Rated load capacity 5000kg | Operating weight of the whole machine

Bucket capacity 2.8 (2.7-4.5) m ³

Walking mode: tire type

Universal type for working conditions and purposes

The overall length of the machine is 8825mm

The overall width of the machine is 2845mm

The overall height of the machine is 3423mm

Minimum ground clearance 534mm

Engine model WP10G220E341

Engine type: inline, water-cooled, electronically controlled high-pressure common rail, four valve

Rated power/speed 162/220kW/r/min

Maximum torque/speed 980/1400-1600N · m/r/min

Total displacement 9.726L

Fuel consumption rate ≤ 215g/kW · h

Engine brand Weichai

Transmission model: planetary power shift

Driving speed 1st gear (forward/reverse) 0-13/0-17km/h

Driving speed 2nd gear (forward/backward) 0-38km/h

Driving brake form: air top oil caliper disc

Parking brake form: electric pneumatic control, internal expansion shoe type

The Lingong L955F loader is equipped with a Weichai WP10G220E341 engine that features a reduced speed for energy conservation. By rationally matching the transmission system, it not only enhances the power performance but also ensures that the machine operates in the low fuel consumption zone of the diesel engine under common working conditions. It is characterized by low speed and high torque, offering strong power and high reliability. It is equipped with a self-made transmission box and a reinforced drive axle, both of which are highly reliable. The front and rear frames adopt a reinforced structure, ensuring high strength and long service life. With an axle distance of 3200mm, it provides more stable operation during work and travel. The articulated parts are designed with a composite structure of tapered roller bearings and spherical plain bearings, making it more adaptable to harsh working conditions. In the working device's hydraulic system, the lifting cylinder is thickened to provide greater lifting capacity. The hydraulic pipelines adopt a double-sealing structure, ensuring high reliability.

Maintenance and Care

As an indispensable piece of machinery in construction projects, loaders are crucial for the progress of the project. Regular maintenance and care of the loaders not only prolongs the service life of the equipment but also ensures the stability of its working performance and reduces the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine, and perform maintenance or replace components if necessary;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.