The Liugong 835N loader adopts mature and reliable core components, with high transmission efficiency and fast operation speed, which can meet the needs of efficient operation, effectively improve work efficiency, shorten operation time.

The Liugong 835N loader is the flagship model of the Liugong N series, a 3-ton loader suitable for medium-scale operations. It features mature and reliable core components, with high transmission efficiency and fast operation speed, capable of meeting the demands of efficient operations. It is widely used in municipal engineering, animal husbandry, housing construction, road construction, etc. It is an excellent loader. The production date of this vehicle is 2023, with original paint, slight vehicle usage traces, and a working duration of 800 hours. It has excellent performance!

About LiuGong 835N

Rated load capacity 3000kg

Rated power 92kW

Bucket capacity range 1.5-3m ³

Standard bucket capacity 1.7m ³

Maximum excavation force 105kN

The overall length of the machine is 7177mm

Bucket outer width 2460mm

The overall height of the machine is 3310mm

Wheelbase 2870mm

Unloading height 3210mm

Work quality 10000kg

Performance Characteristics

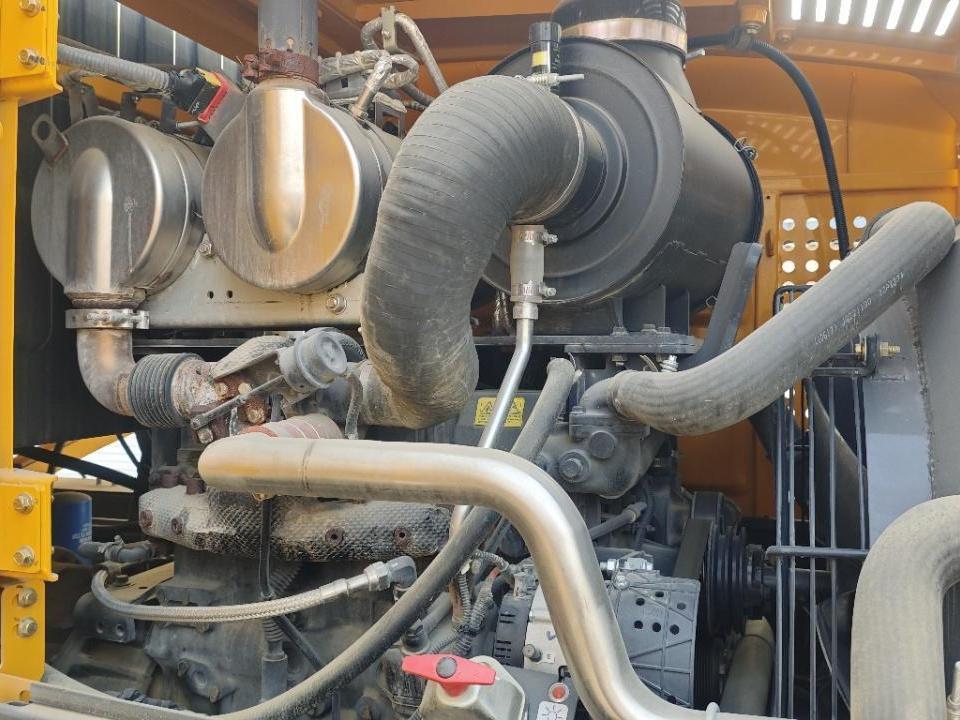

The cab of the 835N loader adopts a panoramic glass window design, providing a wide field of vision. It is equipped with a mechanical suspension seat that can effectively absorb shocks and vibrations, reducing the fatigue of the operator. The multi-directional adjustable seat and the front and rear adjustable steering wheel are suitable for operators of various body types to adjust to a comfortable operating position. The open three-section engine hood design enhances the convenience of overall maintenance and repair; components such as the oil filter, fuel filter, and dual transmission oil filter are all placed in prominent positions, facilitating daily inspection and maintenance. The frame has been thickened and strengthened, enabling it to resist torsion and increase durability; key structural components are analyzed using finite element methods to ensure they can meet various heavy-load working conditions; the robot welding seams are firm, and the overall structure is more robust and durable.

Maintenance And Servicing

Loaders, as indispensable mechanical equipment in construction projects, require efficient and stable operation for the smooth progress of the projects. Regular maintenance and servicing of loaders not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine, and perform maintenance or replace components if necessary;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.