A wheel loader is a heavy-duty engineering machine designed for loading loose materials, extensively utilized in mining, construction, and roadwork operations.

The LIUGONG 856H wheel loader delivers exceptional performance across diverse operations with its high-power drivetrain and energy-efficient architecture. Equipped with an advanced load-sensing hydraulic system, it achieves significantly reduced fuel consumption while maximizing productivity. The spacious ROPS-certified cab ensures ergonomic control and operational safety. Engineered with reinforced structures to withstand extreme environments, it guarantees long-term reliability. Specifically designed for earthmoving, aggregate handling, mining extraction, and road construction applications, this machine stands as an optimized solution for modern engineering projects, empowering users to conquer demanding tasks with maximum efficiency.

In the realm of used construction machinery, our company operates like a seasoned artisan, honing our craft for decades. We specialize in exporting pre-owned equipment, yet fundamentally differ from competitors by never leading with price discussions. Why? Because true value lies not in bargain tags, but in a machine’s proven endurance against jobsite grit and relentless operational demands. Our core principle: Equipment must retain predominantly OEM-original chassis foundations – never over-restored with superficial cosmetics, but preserved in authentic, structurally sound states. Like ancient trees regenerating through robust roots, these machines maintain innate vitality to sustain renewed productivity.

LIUGONG 856H Wheel Loader Specifications

Standard Operating Condition: 5,000 kg

Maximum Digging Force: ≥170 kN

Traction Force: ≥160 kN

Bucket Capacity: 3.0 m³

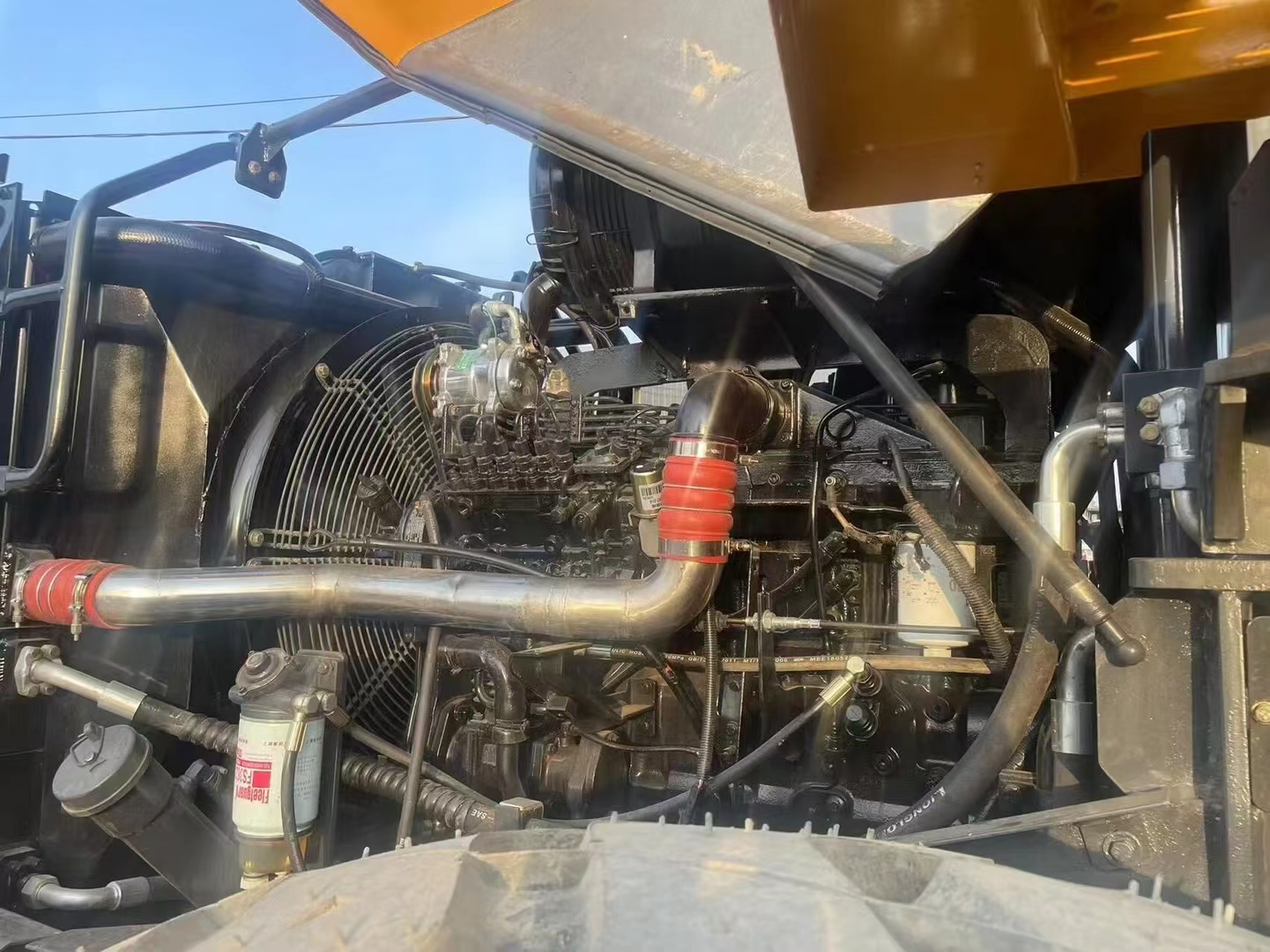

Engine Model: Weichai WP10G220E343

Rated Power/Speed: 162 kW / 2,200 rpm

Maximum Torque: 900 N·m @ 1,400-1,600 rpm

Transmission: ZF 4WG208

Fuel Tank Capacity: 230 L

Fuel Consumption: ≤16 L/h

Max Dumping Height: 3,250 mm

Max Lifting Height: 6,500 mm

Transport Dimensions: 8,450 mm × 2,980 mm × 3,480 mm

Operating Weight: 17,800 kg

Maintenance And Care

As an indispensable mechanical equipment in construction projects, the efficient and stable operation of loaders is crucial for the progress of the project. Regular maintenance and care of loaders can not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

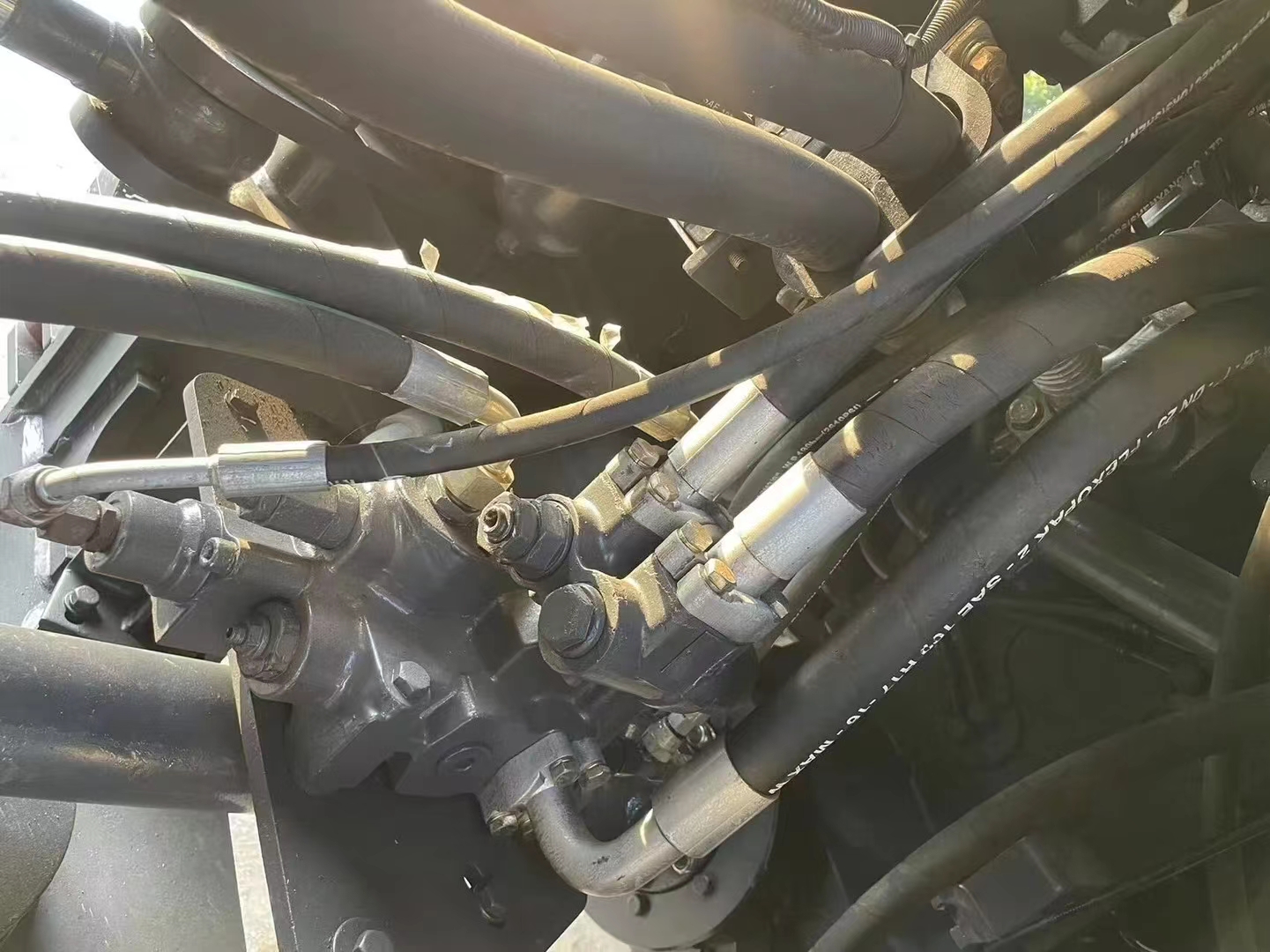

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine. If necessary, perform maintenance or replace components;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.