Adopting advanced fully automatic transmission+FNR control system (technology) to achieve fully automatic shifting, significantly reducing operational intensity and improving work efficiency.

A 2021 Liugong CLG870H loader in near-new condition, with original factory paint all over the vehicle. The original owner purchased this equipment but due to the sudden termination of the project they were undertaking, the equipment was left idle. The vehicle was not used much and is now being sold due to a lack of funds. Our engineers conducted a detailed inspection and evaluation of this vehicle and concluded that it is an extremely excellent and cost-effective loader! It is suitable for large mines, large ports, etc., where there is a long and open space for transportation and large amounts of materials need to be loaded and unloaded. It can efficiently complete loading and unloading tasks!

About Liugong 870H

Overall length (mm) 8773

Overall width (mm) 3220

Overall height (mm) 3467

Minimum ground clearance (mm) 460

Bucket width (mm) 3220

Wheelbase (mm) 3450

Track width (mm) 2280

Unloading height - Unloading angle of 45 ° (mm) 3000

Steering angle (°) 38

Minimum turning radius (based on the center of the outer wheel) (mm) 6300

Boom lifting time (s) 5.2

Three items and time (s) 10

Rated load capacity (kg) 7000

Operating weight of the whole machine (kg) 21500

Bucket capacity (m ³) 4.2

Maximum excavation force (excavation force) (kN) 200

Maximum Traction Force (kN) 192

Walking mode: tire type

Tonnage range 5-8 tons

Engine type: six cylinder inline, four stroke turbocharged, intercooled

Rated power/speed (kW/r/min) 180/2200

Maximum torque/speed (N · m/r/min) 1187

Total displacement (L) | 9.3

Performance Features

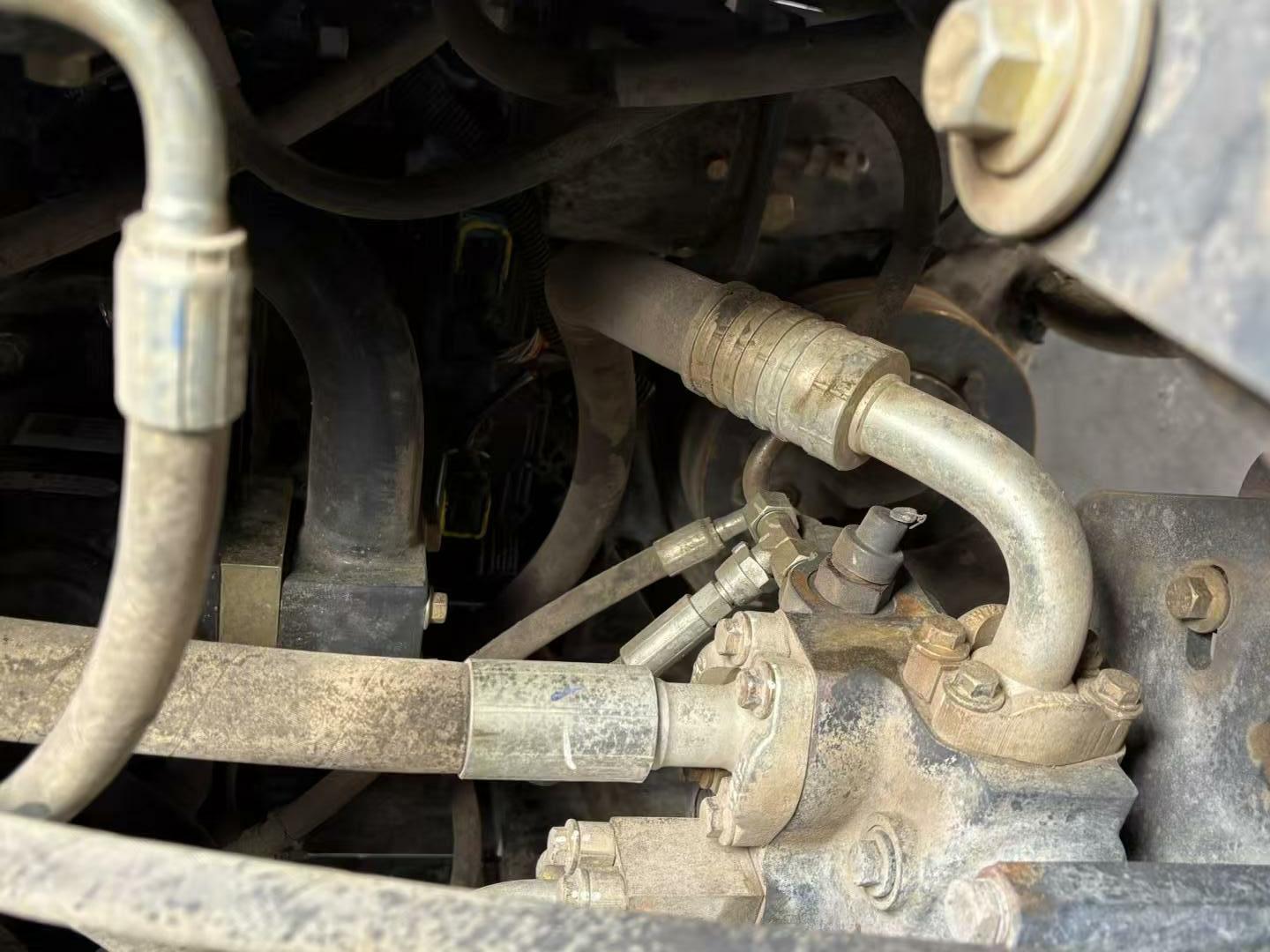

The Liugong CLG870H loader is equipped with a Cummins QSL9.3 engine, with a rated power ranging from 180 to 210 kW, and a maximum torque of 1187 N·m. The low-speed-high-torque design is suitable for heavy-load conditions. It improves efficiency while reducing fuel consumption (the measured energy consumption per ton of material is 33% lower than that of a 5-ton model). It enhances the overall stability of the machine and the working quality reaches 21.5 - 23.3 tons. A single-layer horizontally-mounted radiator increases the heat dissipation efficiency by 5%, is suitable for 50°C high-temperature environments, and is easy to maintain. The articulated parts use tapered roller bearings, which enhance the torsional resistance.

Maintenance And Servicing

Loaders, as indispensable mechanical equipment in construction projects, require efficient and stable operation for the smooth progress of the projects. Regular maintenance and servicing of loaders not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine, and perform maintenance or replace components if necessary;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.