This is a 2019 Shangong 653D wheeled loader. Previously, the machinery was working in a sand washing plant in China. The working environment was monotonous and the daily maintenance of the machinery was very good. The working hours were 4800 hours. Although the working time was longer than that of some excavators, the vehicle condition remained very good, and the price was also very reasonable!

Detailed Parameters

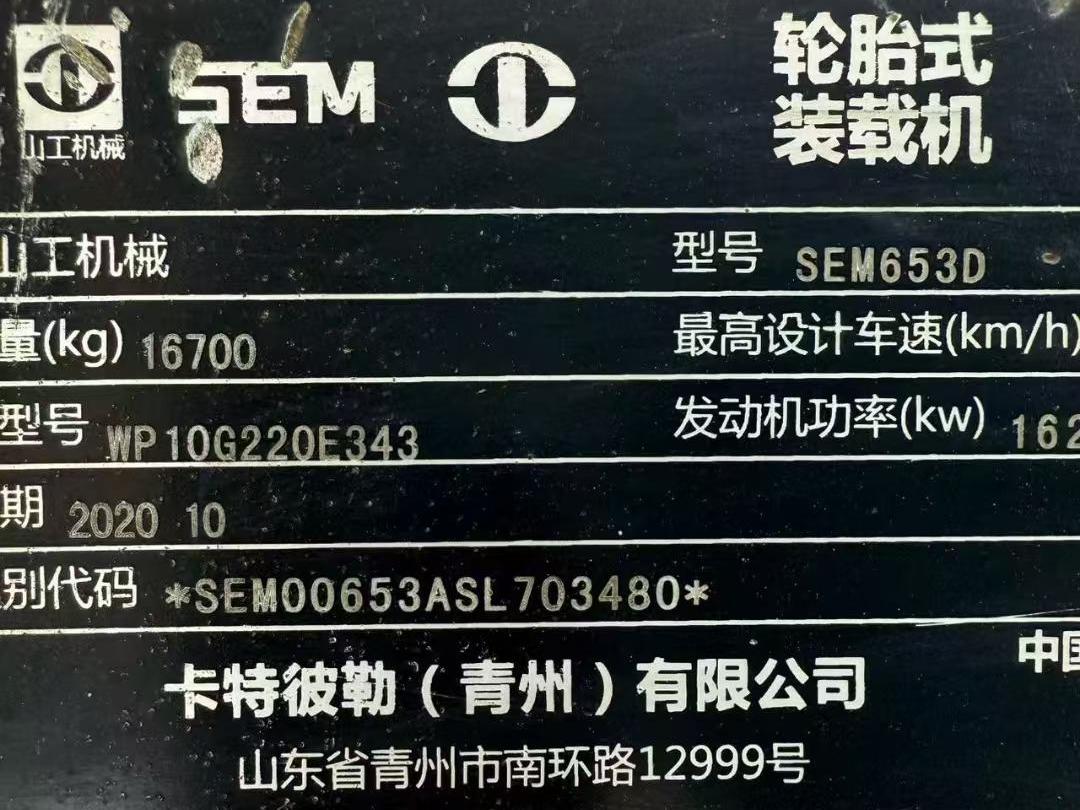

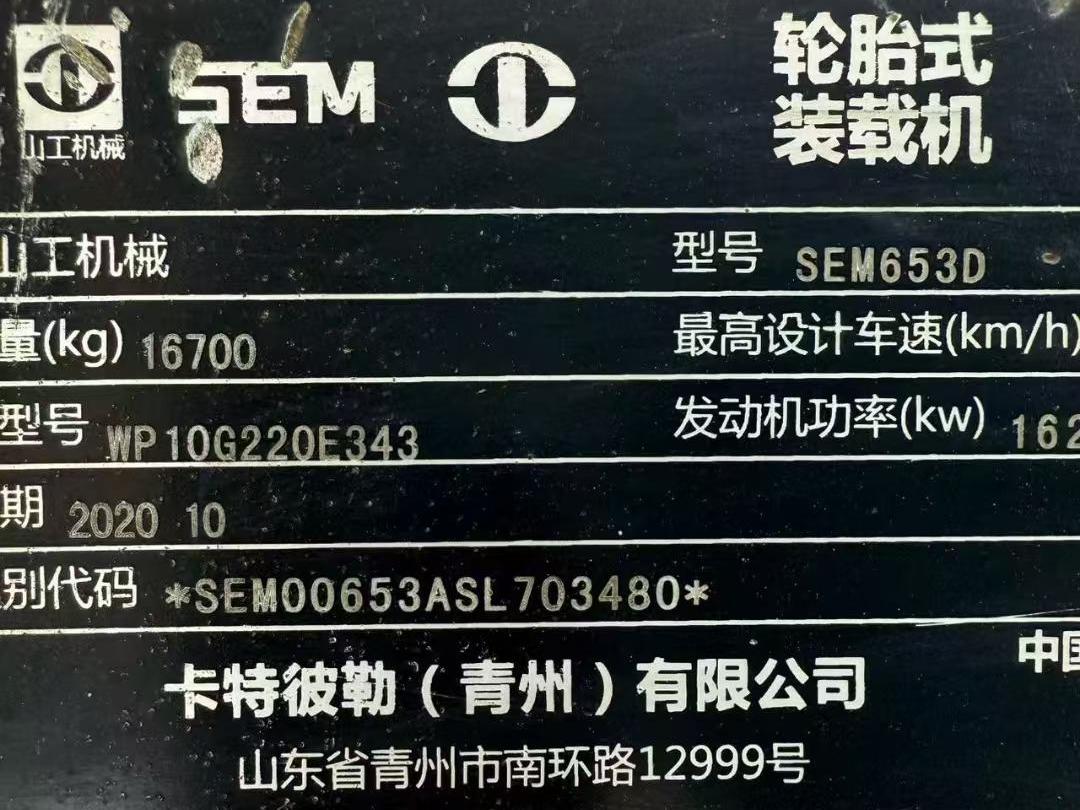

Brand SHANGONG

Model SEM653D

Factory Year 2019

Tonnage Range 4 - 5 tons

Engine Brand Weichai

Engine Model WP10G220E343

Rated Power/RPM 162/2000 kW/r/min

Total Displacement 9.7L

Rated Load Capacity 5000kg

Total Machine Operating Weight 16700kg

Bucket Capacity 2.7 - 4.5m³

Performance Features

The Shangong 653D wheeled loader adopts a heavy-duty frame and a mature fixed-axis transmission system, which extends the major overhaul cycle for heavy-duty operations compared to previous models. The fixed-axis transmission has a simple structure, and key components have been optimized for design, resulting in higher reliability and longer lifespan. The optimized torque converter is better matched with the engine, achieving higher efficiency. Equipped with the Wuchai engine model WP10G220E343, with a rated power of 162kW at 2000rpm and an engine displacement of 9.7L, it offers powerful performance and can meet the operational requirements of various different working conditions. Utilizing the Caterpillar cooling system, it is efficient and reliable, enabling better thermal balance between water temperature and oil temperature, allowing all components to operate at optimal temperatures.

Maintenance And Care

As an indispensable piece of equipment in construction projects, the efficient and stable operation of a loader is crucial for the progress of the project. Regular maintenance and care of the loader can not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks

2. Replace the engine oil and oil filter every 250 hours of work or monthly

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine, and perform maintenance or replace components if necessary

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.