The XGMA ZL50 loader is engineered for material loading and short-haul transport operations at construction and mining sites.

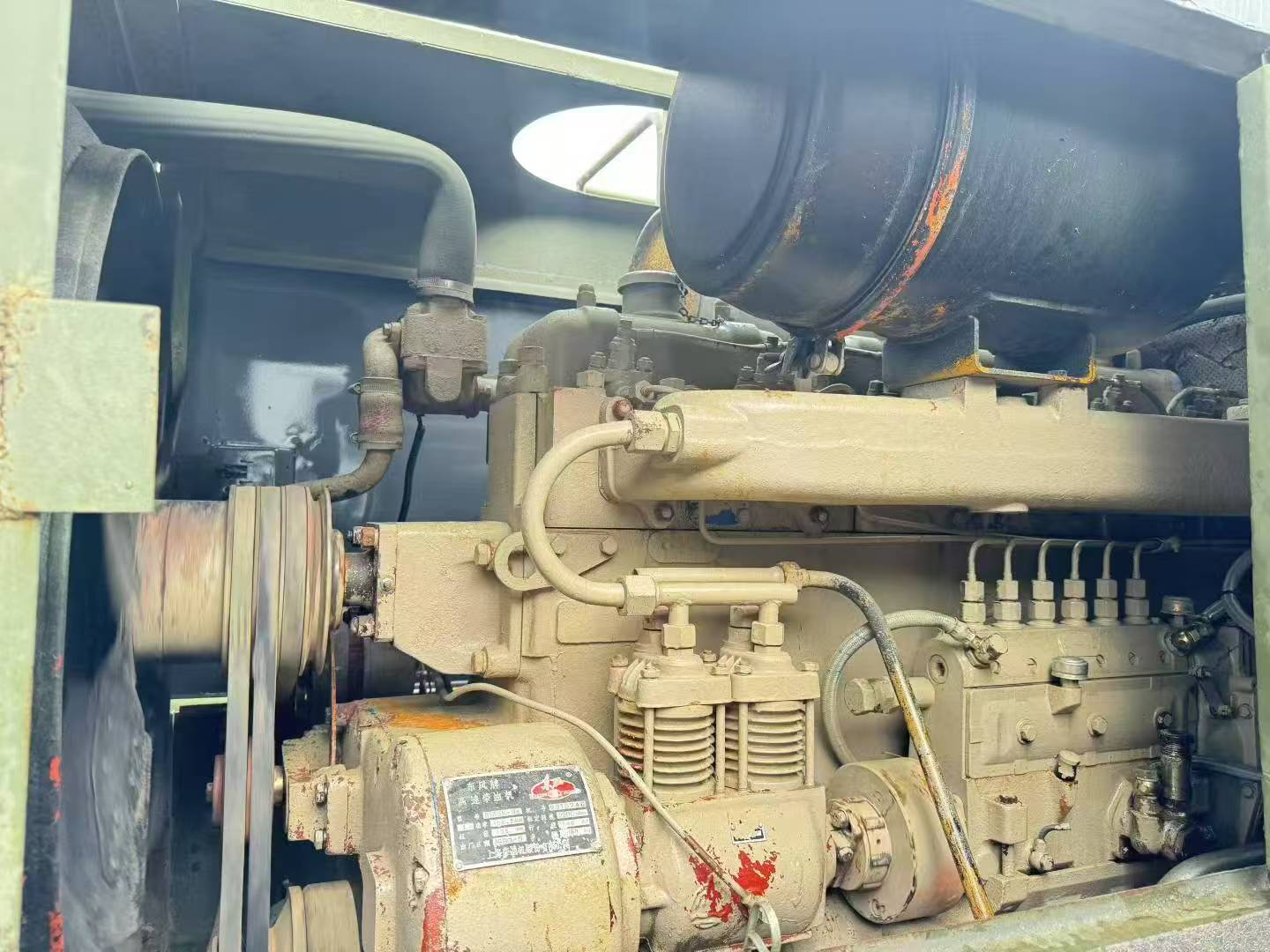

This decommissioned XGMA ZL50 loader from a Chinese state unit records only 2,000+ operational hours, exhibiting near-new condition! Its exceptional state stems from rigorous maintenance protocols and standardized operation: Serviced by dedicated personnel with zero overloading/abuse; Ultra-low utilization preserving pristine cabin interiors; 90%-tread tires with uncompromised power delivery. Currently in flawless working order, it delivers unmatched cost-efficiency for diverse engineering applications.

When clients approach us, we never rush batches of refurbished loaders onto the market. Instead, we initiate in-depth consultations: Will this machine handle heavy-duty payloads in African mines? Or manage precision loading in Southeast Asian ports? We meticulously tailor refurbishment plans to your operational DNA, whether installing deep-tread tires, reinforcing chassis structures, or calibrating engines to factory specs. Ultimately, the refurbishment blueprint isn't dictated by us, but masterminded by you. The resulting equipment delivers not just guaranteed performance, but carries your operational imprint. It transcends being mere machinery to become your steadfast workhorse and comrades-in-arms.

XGMA ZL50 Wheel Loader Specifications

Model: ZL50

Rated Load Capacity: 5,000 kg (5 tons)

Bucket Capacity: 3.0 m³

Max Digging Force: 150 kN

Max Traction Force: 140 kN

Operating Weight: 16,500 kg

Engine: Weichai WD10G220E23

Rated Power: 162 kW

Transmission: Fixed-Shaft Power Shift Transmission

Fuel Tank Capacity: 220 L

Hydraulic System Capacity: 200 L

Dimensions (L×W×H): 7,410 mm × 2,990 mm × 3,240 mm

Minimum Turning Radius: 6,450 mm

Maintenance And Care

As an indispensable mechanical equipment in construction projects, the efficient and stable operation of loaders is crucial for the progress of the project. Regular maintenance and care of loaders can not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine. If necessary, perform maintenance or replace components;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.