A wheel loader is a wheeled heavy machinery unit equipped with a front-mounted bucket, designed for loading and transporting bulk materials such as soil, sand, or gravel. It is extensively utilized in construction and mining operations.

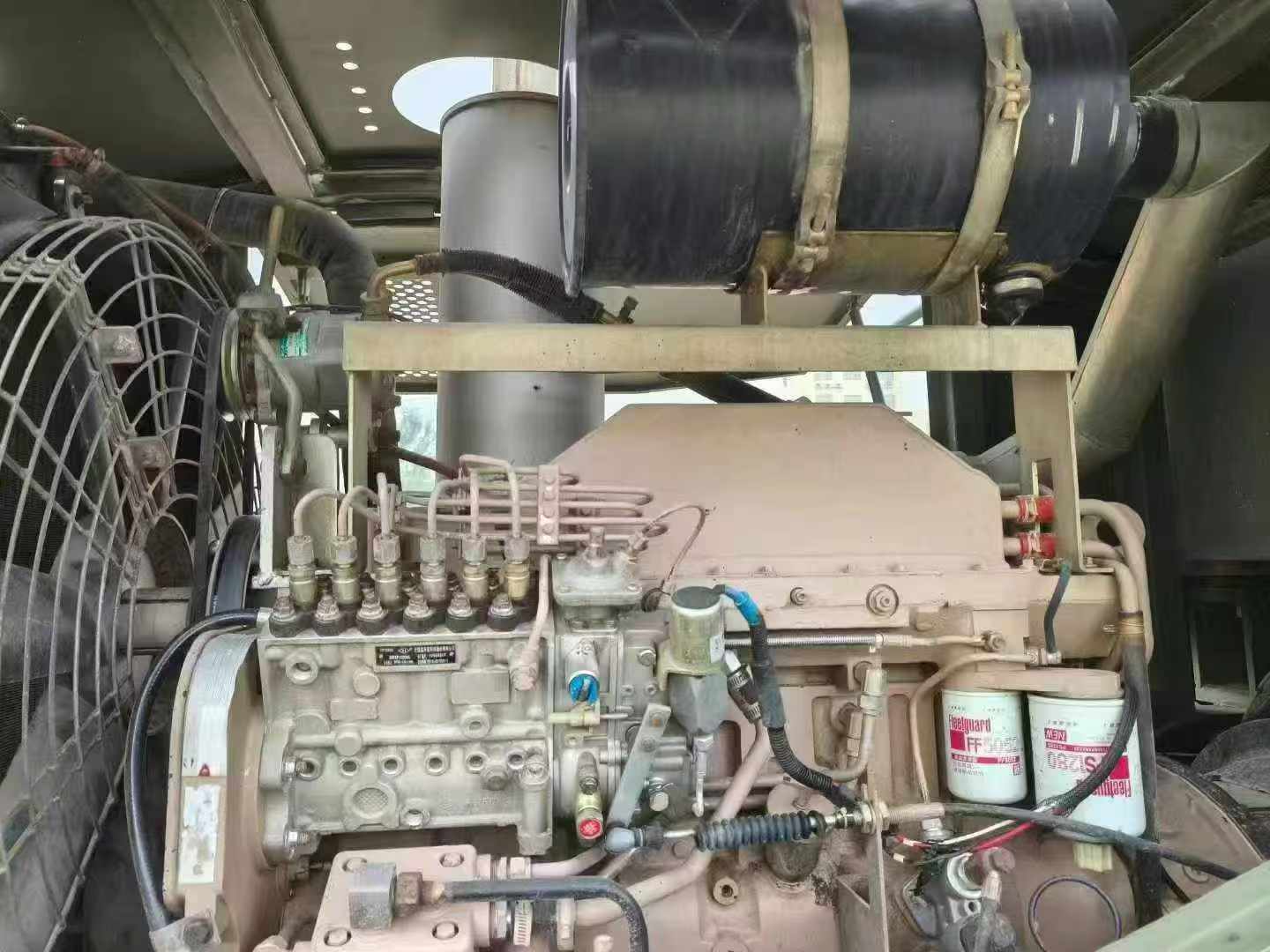

This state-unit decommissioned loader retains 80% original factory paint with intact surfaces and zero structural damage. During active service, it primarily executed standardized operations including base infrastructure development, training ground leveling, and combat-ready material transport. Documented operational history confirms stable working conditions without overload incidents. Equipped with a Shangchai direct-injection engine delivering robust power, exceptional fuel efficiency, and extended maintenance intervals,fully adaptable to high-altitude/low-temperature extremes. The unit enforced strict scheduled maintenance protocols, ensuring optimal hydraulic and drivetrain performance with precise operational responsiveness. Post-decommissioning foundational adjustments enable immediate deployment in aggregate handling and site clearance operations, offering exceptional cost efficiency.

The principle of 'Authentic Core Machinery' is not merely a slogan here,it's our operational bedrock. For every piece of equipment destined for overseas deployment, we conduct thorough provenance verification. Has it endured abusive operation? Does its structural frame bear hidden damage? Are critical components preserved as manufacturer-specified? These factors outweigh superficial refinishing by orders of magnitude. Like master equestrian judges examining a steed, we prioritize skeletal integrity over glossy coats. We stake our reputation on this truth: Only machinery with time-tested structural soundness can survive the crucible of foreign job sites.

XGMA ZL50G Wheel Loader Specifications

Model: ZL50G

Rated Load Capacity: 5,000 kg

Bucket Capacity: 2.7 m³

Max Digging Force: 150 kN

Max Traction Force: 140 kN

Operating Weight: 16,800 kg

Engine: Weichai WD10G220E30

Rated Power: 162 kW

Transmission: Fixed-Shaft Power Shift Transmission

Fuel Tank Capacity: 260 L

Hydraulic System Capacity: 200 L

Dimensions (L×W×H): 8,050 mm × 3,000 mm × 3,450 mm

Minimum Turning Radius: 6,650 mm

Maintenance And Care

As an indispensable mechanical equipment in construction projects, the efficient and stable operation of loaders is crucial for the progress of the project. Regular maintenance and care of loaders can not only extend the service life of the equipment but also ensure the stability of its working performance and reduce the failure rate.

1. Clean the air filter and oil filter every 100 hours of work or every two weeks;

2. Replace the engine oil and oil filter every 250 hours of work or monthly;

3. Replace the hydraulic oil and hydraulic filter every 500 hours of work or quarterly; Check the engine valve clearance and make adjustments;

4. Replace the transmission oil and drive axle gear oil every 1000 hours of work or every six months; Check and replace the diesel filter and air filter of the engine; Check and adjust the operation of the engine. If necessary, perform maintenance or replace components;

5. The lubricating oil of the loader is crucial for the normal operation of the equipment. Strengthen the lubrication at each lubrication point. It is recommended to add lubricating grease to the lubrication points every shift to reduce mechanical wear and extend the equipment's lifespan.