Abount Sy485

Description

- Model: SY485

- Operating Weight: Approximately 47,000 kg

- Bucket Capacity: 2.0–3.2 m³

- Engine: Equipped with a powerful diesel engine (specific model may vary by version) delivering around 250 kW

- Max Digging Depth: About 7,000 mm

- Bucket Digging Force: Up to 300 kN

- Swing Speed: Approximately 8.5 rpm

- Travel Speed: 5.2 km/h (max)

- Fuel Tank Capacity: Around 500 L

Applications

Construction projects (foundation digging, site preparation)

Mining and quarrying (extracting aggregates, overburden removal)

Road building (excavating trenches, grading)

Demolition (with specialized attachments)

Agricultural and forestry operations (land clearing, pond digging)

Performance characteristic

- Power System: It is equipped with an Isuzu 6WG1 engine, with a rated power of 310kW/1800rpm.The engine has a large displacement, sufficient torque reserve, and stable output within the effective working range, which can easily handle super - hard rocks and large - scale earthwork operations.

- Hydraulic System: The main hydraulic pump adopts the Kawasaki K5V212 positive - flow pump, and the main valve is the Kawasaki KMX32NA hydraulic control multi - way valve. The unique AOCT self - optimizing control technology realizes the perfect matching between the engine and the main pump, achieving high efficiency and low fuel consumption.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2.Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3.Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

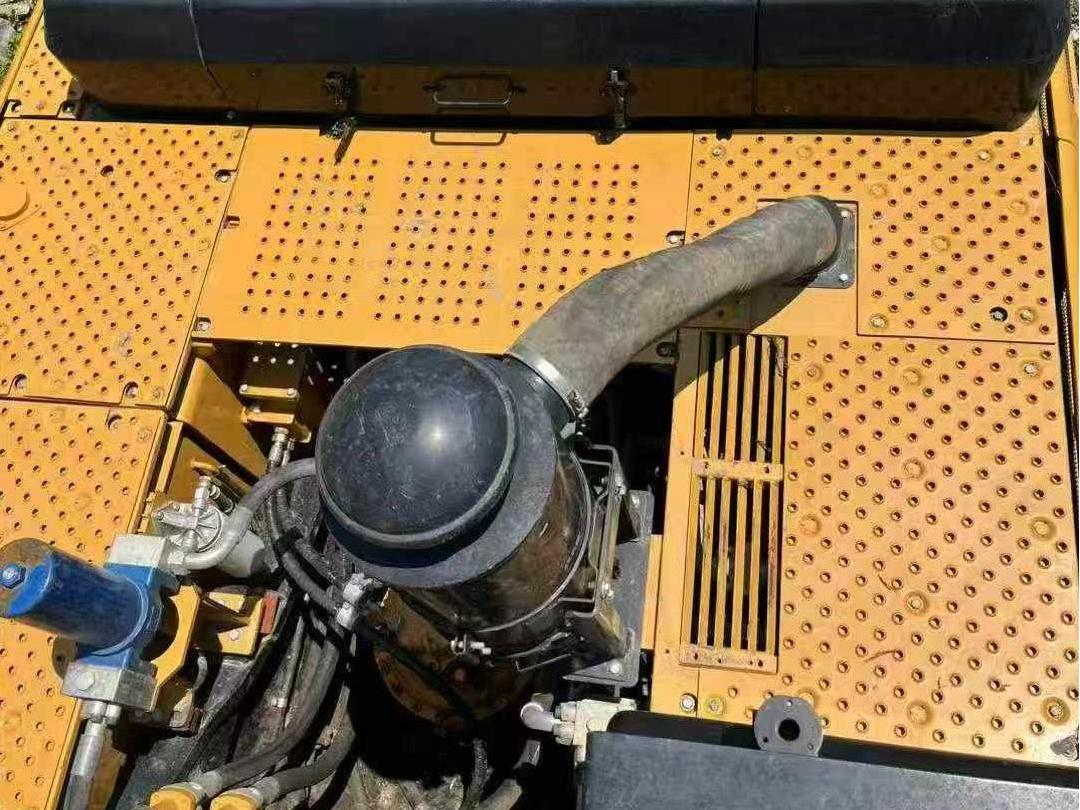

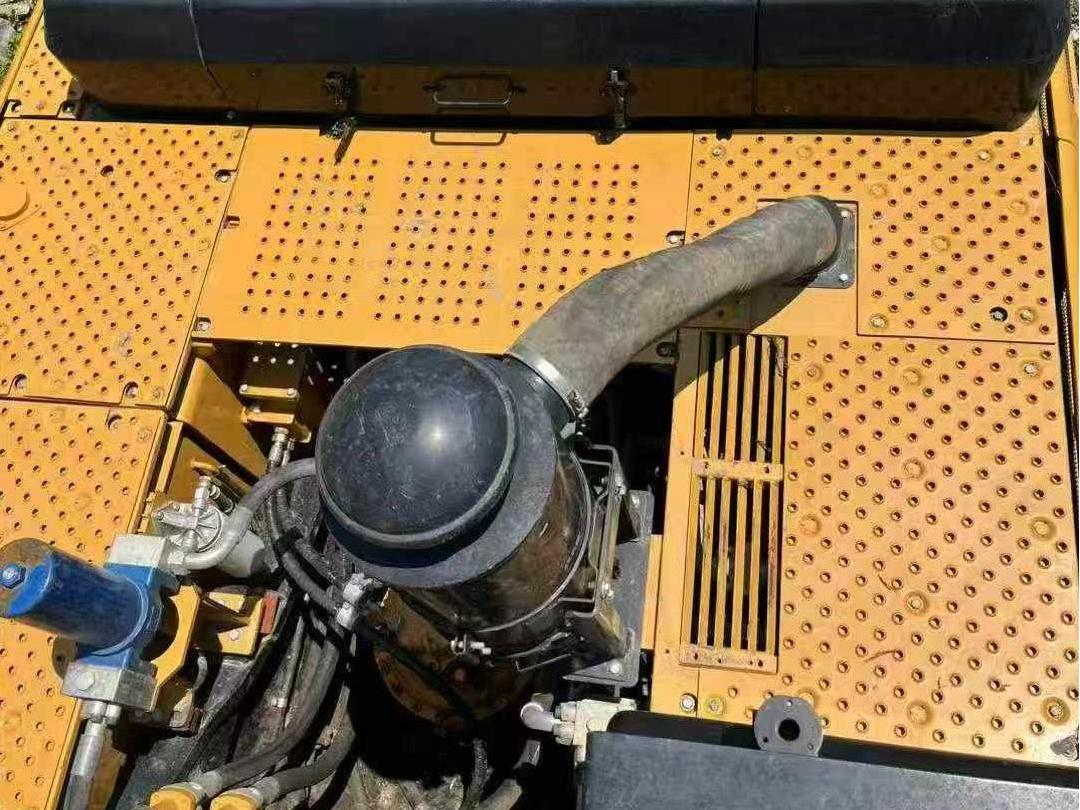

4.Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5.Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6.Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8.The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.

Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured