The 16-ton bulldozer delivers robust power, efficient dozing performance, and multi-terrain adaptability, while also featuring structural durability and precise maneuverability

2015 military-demolition Yishan 160 bulldozer. Original military configuration with winch and roll-over protective structure (ROPS). Automatic transmission ensures user-friendly operation. 3.9-meter front blade enables high-efficiency earthmoving. Powered by a Cummins heavy-duty engine delivering robust performance. Logged merely 100+ operating hours over a decade, with mechanical condition rivaling brand-new units

Low-cost machinery is like a tempting promissory note:

The money saved at contract signing will always be repaid with interest in the repair shop. We've witnessed too many buyers trapped in this vicious cycle,saving 30% on procurement, only to spend 50% extra on replacement parts, plus paying for production downtime. Price wars are sprints, but quality is a marathon. When clients finally understand: Every penny saved shouldn't become future debt, they'll read the rust on our machines as promises more valuable than fresh paint

Detailed Specifications for Yishan QSL160 Bulldozer

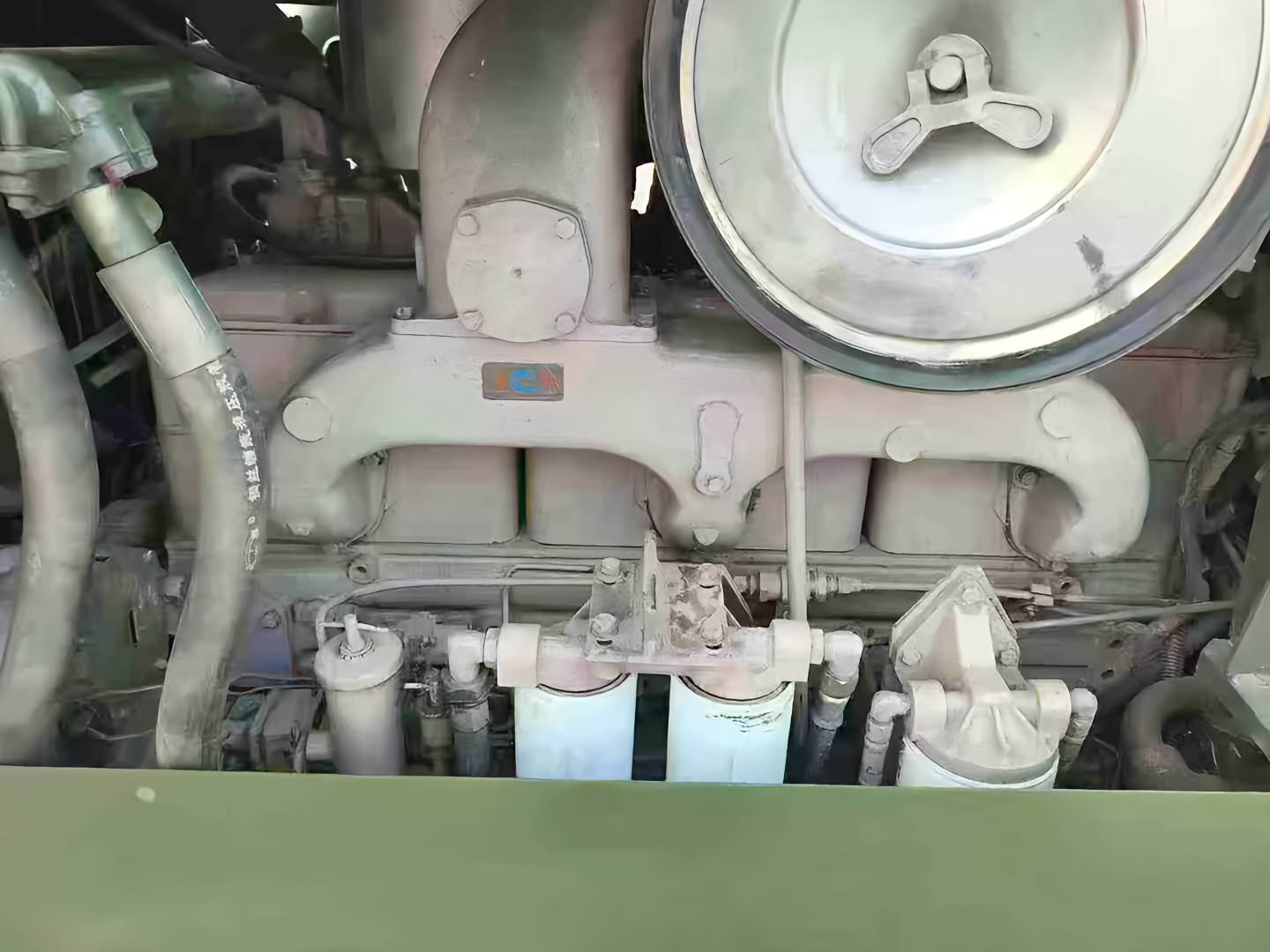

Engine Model: Cummins QSL9

Engine Type: In-line six-cylinder turbocharged diesel engine

Rated Power: 270 HP (approx. 201 kW) @ 2000 rpm

Max. Torque: 1200 Nm @ 1300–1600 rpm

Blade Dimension: 3.9m width (tilt-capable, optimized for high-efficiency earthmoving)

Transmission: Automatic gearbox (user-friendly operation with torque converter)

Attachments:

Standard hydraulic winch (towing capacity: 10 tons)

Operating Weight: 16.8 tons

Overall Dimensions : 7500 mm × 3900 mm × 3200 mm

Daily Maintenance

1. Engine oil, hydraulic oil, coolant, and fuel level checks

Inspect levels and replenish to standard if insufficient; observe for leakage traces.

2. Air cleaner filter dust removal

Clean dust from air filter elements (require shift-based cleaning in dusty environments); check diesel filter water sedimentation and drain.

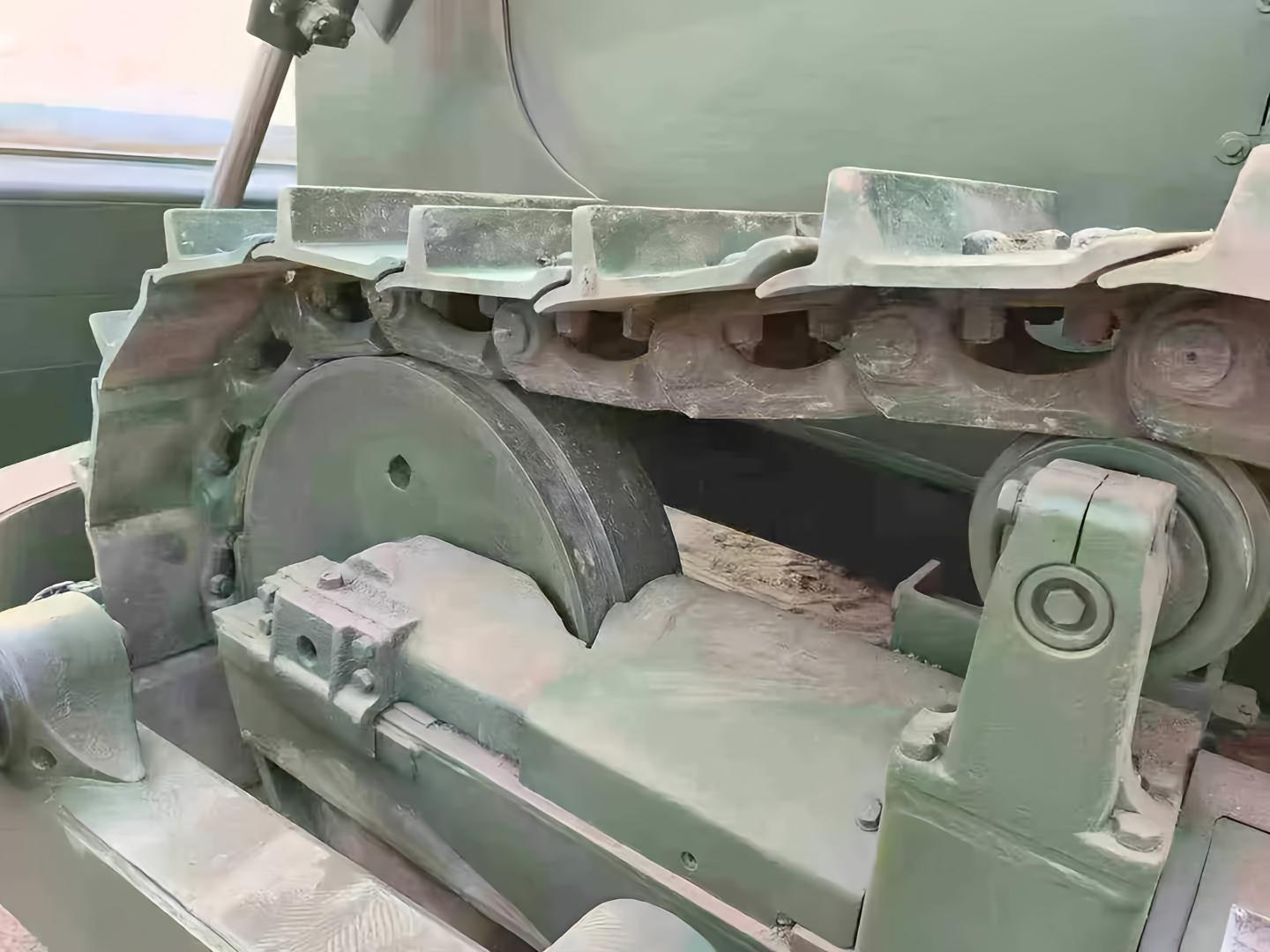

3. Undercarriage system maintenance

Adjust track tension to specified value (excessive looseness/tightness accelerates wear); remove rocks and mud between track plates; inspect lubrication status of idler wheels and carrier rollers.

4. Structural components and safety devices

Tighten blade and ripper connection bolts; check brake system and steering control sensitivity; ensure lights, horn, and fire extinguisher are functional.

5. Machine cleaning

After shutdown, remove debris from radiator grille and dirt from the machine body to prevent clogging and corrosion.