Bulldozers are suitable for construction sites, mines, and complex terrain environments, efficiently leveling land and removing obstacles.

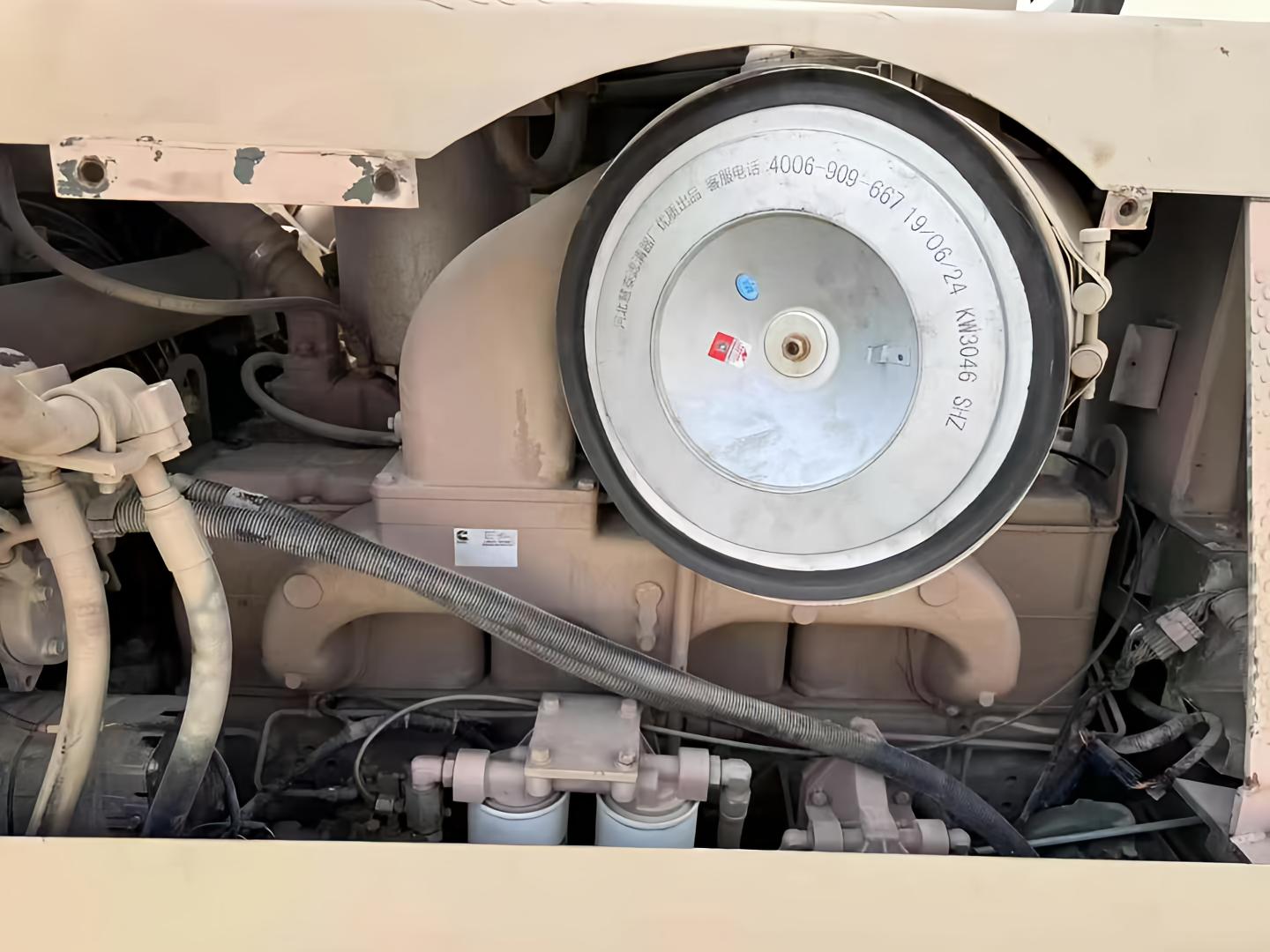

2015 retired Pengpu 160 bulldozer from a certain unit, equipped with a Chongfa Cummins engine, automatic transmission for easy operation, and a rear-mounted winch with powerful functionality. Blade width of 4 meters, only worked over 100 hours, stored as inventory with condition like new. Military-grade quality, super value and practical

In the used bulldozer market, many focus solely on price tags while overlooking the total cost. Low-priced machines often require major repairs soon after purchase, with hard-to-find parts causing project delays and even safety hazards. We advocate long-term investment: A high-quality used bulldozer, rigorously vetted by us, runs efficiently for years like new. Clients exporting to the Middle East often say desert projects fear equipment failure most,yet our bulldozers withstand sandstorms and extreme heat. Because we’ re not after quick profits, but building reputation. Every deal plants a seed,savings on repairs and downtime losses bloom into more orders. Quality isn’t an expense; it’s the smartest investment.

PENGPU PD160 Bulldozer Technical Specifications

Engine Model: Cummins 6BT5.9-C160

Rated Power: 160 hp (118 kW) @ 2000 rpm

Displacement: 7.0 L

Fuel Consumption Rate: ≤220 g/kW·h

Cooling System: Forced water-cooling circulation

Blade Type: Straight tilt blade

Blade Capacity: 3.8 m³

Max. Dozing Depth: ≥450 mm

Max. Cutting Depth: ≥300 mm

Drawbar Pull: 130~140 kN

Operating Weight: 16.8 tonnes

Overall Dimensions (L×W×H): 5,260 mm × 3,380 mm × 3,080 mm

Daily Maintenance

1. Engine oil, hydraulic oil, coolant, and fuel level checks

Inspect levels and replenish to standard if insufficient; observe for leakage traces.

2. Air cleaner filter dust removal

Clean dust from air filter elements (require shift-based cleaning in dusty environments); check diesel filter water sedimentation and drain.

3. Undercarriage system maintenance

Adjust track tension to specified value (excessive looseness/tightness accelerates wear); remove rocks and mud between track plates; inspect lubrication status of idler wheels and carrier rollers.

4. Structural components and safety devices

Tighten blade and ripper connection bolts; check brake system and steering control sensitivity; ensure lights, horn, and fire extinguisher are functional.

5. Machine cleaning

After shutdown, remove debris from radiator grille and dirt from the machine body to prevent clogging and corrosion.