A bulldozer is a kind of engineering machinery widely used in fields such as mining, water conservancy, construction, ports, agriculture and forestry, and national defense projects. It is mainly used for earthwork operations such as scooping, transporting, unloading soil and stones, and site leveling.

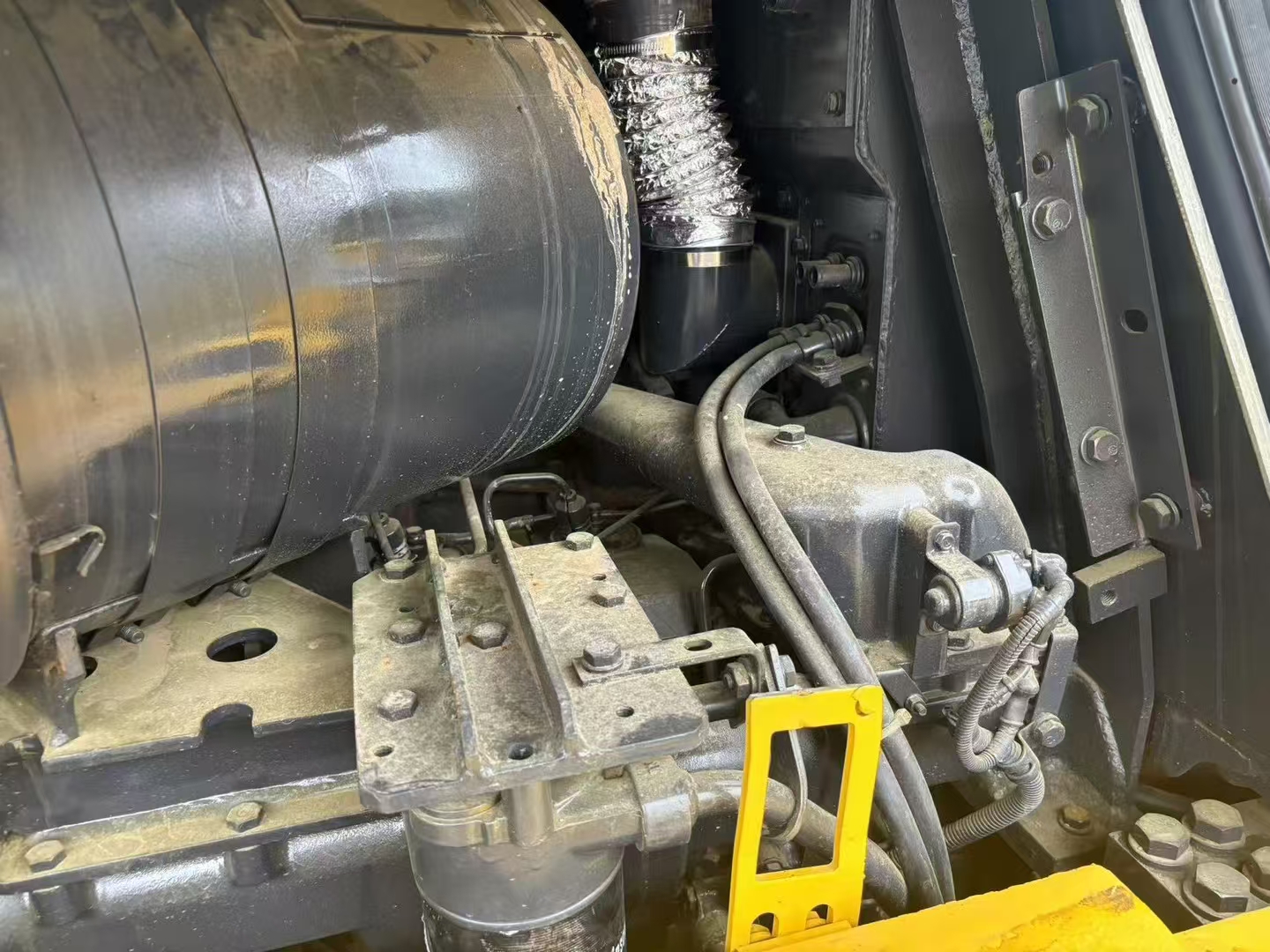

The Komatsu 85ESS bulldozer has been in operation for 6,700 hours in 2020. Regular maintenance was carried out during its usage period, and the vehicle is in good condition. Cold start tests were conducted on the vehicle, and the engine started smoothly without any blue smoke. The lifting and lowering of the dozer blade is smooth and without delay. The main components of the Komatsu 85ESS bulldozer are made of high-strength materials and processed with advanced techniques, enabling it to withstand long-term and high-intensity work, and it has a long service life and reliable performance.

Detailed parameters

Overall machine working weight (kg): 28000

Engine model: SA6D125E - 3

Flywheel power (kW): 179

Total displacement (L): 11.04

Engine oil (L): 40

Coolant (L): 93

Performance Features

Equipped with a unique turbocharged engine from Komatsu, it offers powerful output and can easily handle various loads and working conditions during operation. It is equipped with an advanced hydraulic transmission system, enabling rapid excavation and earthmoving operations, thereby enhancing work efficiency.

It adopts an accurate electronic control system, enabling precise operation and a high degree of automation. The bulldozer features a spacious and comfortable cab, with adjustable seats, easy operation, and adjustable sensitivity of the handles and pedals, providing a comfortable working environment and a good working experience for the operator. It is equipped with sturdy and durable cutting tools and a large-capacity bucket, capable of easily completing various excavation and earthmoving operations, with strong grip and excavation capabilities.

In order to ensure that our quality can satisfy and reassure our customers,

we will conduct detailed inspections on every excavator to guarantee that each one is in good working condition. Before the mechanical equipment is dispatched, we will replace new engine oil, hydraulic oil, gear oil, new air filters, oil filters, diesel filters, valve core sealing rings, fuel injectors, pin shafts, and other damaged parts with new components.

Daily maintenance for bulldozers:

50 hours or monthly maintenance:

Apply lubricating grease to multiple parts, such as the fan pulley, tension pulley, etc. Replace the oil filter cartridge of the transmission oil filter and the oil filter cartridge of the steering gear oil filter. Clean or replace the engine air filter.

500 hours or three months maintenance:

It is necessary to replace the engine oil pan oil and replace the oil filter cartridge and the bypass filter cartridge of the oil filter, replace the engine fuel filter cartridge, check and replenish the final transmission oil level and the hydraulic oil tank oil level.

1000 hours or six months maintenance:

Apply lubricating grease to each control shaft, universal joint, tension cylinder, etc. Check and replenish the oil levels of the supporting wheel, drag wheel, guiding wheel, replace the rear axle box, transmission, and torque converter, replace the oil and replace the fine filter cartridge, clean the coarse filter, replace the hydraulic oil tank oil and replace the fine filter cartridge, clean the coarse filter, check and replenish the oil level of the final transmission box.