XCMG QY16KJ 16-ton Truck Crane Specification

XCMG QY16KJ embodies the core principles of "High Efficiency, Safety, and Energy Conservation", engineered for:

Municipal Pipeline Installation

Compact Steel Structure Erection

Landscaping Equipment Lifting

Emergency Response Operations

Government-surplus near-new 2012 XCMG QY16KJ truck crane. Features three-section boom with jib, 10 near-new tires (spare tire unused), and pristine cabin interior!

We specialize in global export of premium-quality used truck cranes. Understanding that lifting operations determine safety, efficiency, and project success, we never compromise through ' low-price ' gimmicks. Instead, we treat every unit's mechanical integrity and reliability as our lifeline. Choosing us means choosing operational confidence, hassle-free performance, and sustained ROI.

By Choosing us, You Gain:

A high-performance used truck crane;

Robust assurance of equipment safety and reliability;

A quality-centric partner for long-term trust;

A strategic asset investment delivering higher ROI.

We don’t sell "cheap" – we deliver enduring value proven through time and heavy-load trials.

XCMG QY16KJ 16-ton Truck Crane Specification

Maximum Lifting Capacity: 16 tons (at 3m radius)

Working Radius: 2.5m-22m

Minimum Rated Load: 0.6 tons (at 22m)

Drive Configuration: 4×2 rear-wheel drive

Maximum Speed: 80 km/h

Gradeability: ≥30%

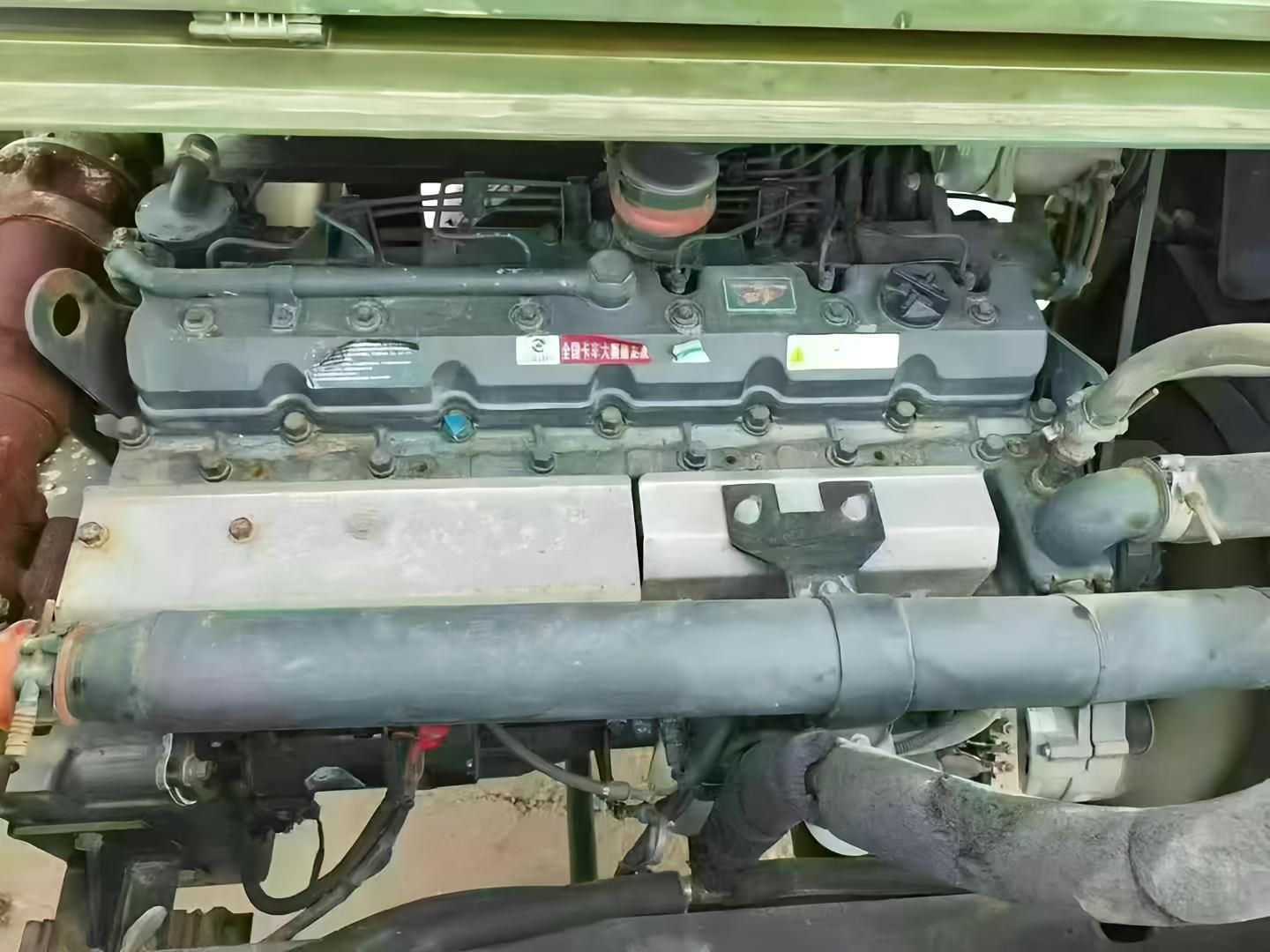

Engine Model: Shangchai SC7H180Q3 diesel engine

Power: 132kW (180 hp)

Fuel Tank Capacity: 200L

Main Boom Length: 10.5m (base section), max 31m (fully extended)

Overall Dimensions: 11.2m × 2.5m × 3.4m

Total Weight: 20.8 tons

Outrigger Span: 5.2m longitudinal × 5.6m transverse

Daily Maintenance for Truck Cranes

1. Regularly inspect tightening conditions of all fasteners, especially slewing bearing bolts.

2. Test brake assemblies of hoisting mechanisms weekly to ensure safety compliance.

3. Maintenance schedule:

- Weekly: Clean/lubricate main boom lower surfaces

- Monthly: Maintain hooks, drive shafts, wire ropes, boom pivot pins

4. Gear oil replacement: Approximately every 12 months. Monitor fluid levels and top up if low.

5. Hydraulic fluid management: Filter or replace every 6 months under normal operation.

6. Pre-operation safety checks: Verify all safety devices daily; repair faults before use.

Mandatory Replacements Before Machinery Shipment

1. Full fluid renewal: Engine oil, hydraulic fluid

2. Filter replacements: Engine oil filter, diesel filter, air filter

3. Wear-prone components: All damaged/deteriorated parts replaced with new OEM-grade components