CAT Excavator 320GX is an economical hydraulic excavator designed to meet users' demands for reliability, ease of operation and economy.The cab design is simple and comfortable, equipped with a high-definition large-screen touch operation panel, achieving keyless start and providing a more convenient control experience.

About CAT320GX Excavator

Description

This is a CAT320GX Excavator Demolition Operation For Burkina Faso.In recent years, due to reasons such as the previous owner's failure to recover funds in a timely manner, the working hours of this model are relatively short, the degree of wear and tear is relatively low, and the cost performance is relatively high. Our company's products are strictly controlled by engineers and are in good condition. At the same time, it has a professional and complete maintenance plan, which can ensure that the machinery is suitable for various working conditions. It can operate perfectly in conventional working conditions such as underground mining, road and bridge construction, water conservancy projects and river management, urban building construction, farmland renovation and ditch excavation, port construction and waterway excavation.

2019 Used Excavator CAT320GX Specificaion

Overall machine length: Approximately 8.8 meters

The overall width of the machine:Approximately 3.4 meters

Overall height: approximately 3.1 meters

Track: 2.7 meters for the front wheel and 3.2 meters for the rear wheel

Maximum excavation radius: approximately 8.1 meters

Operating weight: 19,720 kilograms

Engine model: Cat C4.4 Electronically controlled Engine

Total engine power: 108kw/2000rpm

Bucket capacity: 0.9 cubic meters

Fuel consumption: 12 liters per hour

Performance characteristics

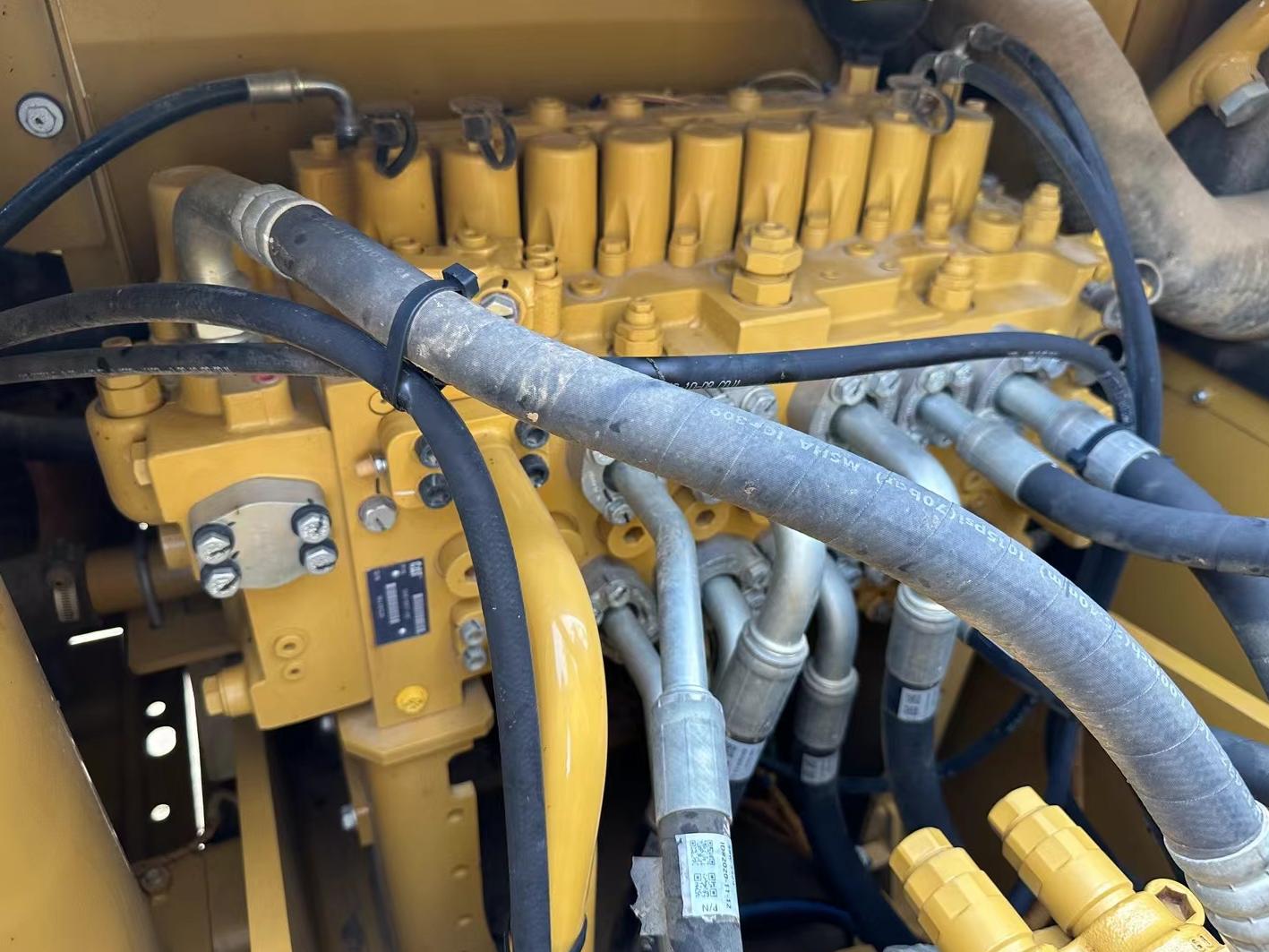

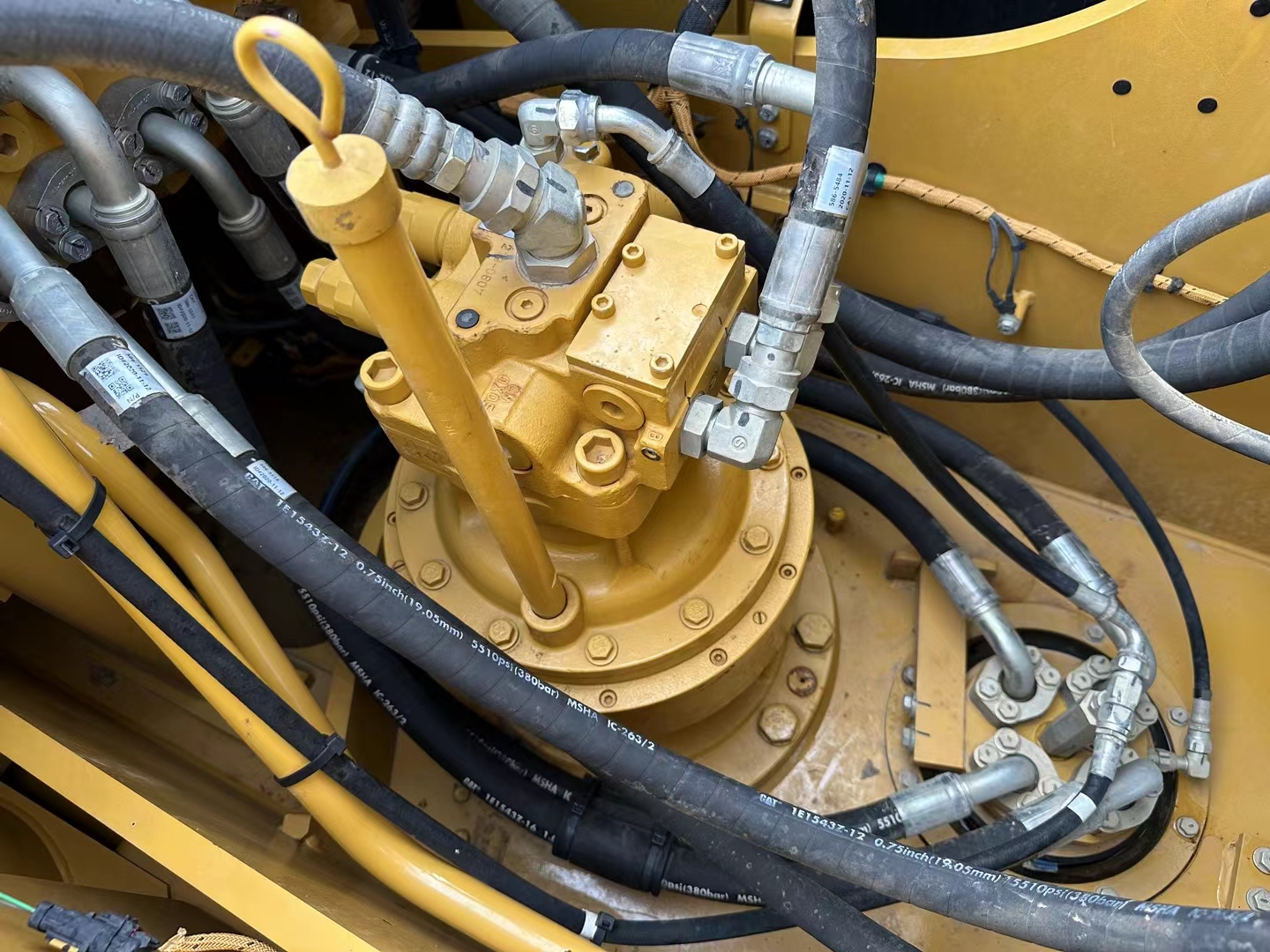

The model performs well in fuel economy, with a fuel-saving rate of up to 15%, and is equipped with an advanced electro-hydraulic system and intelligent power regulation function. In addition, the maintenance cost has been reduced by up to 20%, making maintenance more convenient. Most daily maintenance operations can be easily completed on the ground. The cab design is simple and comfortable, equipped with a high-definition large-screen touch operation panel, achieving keyless start and providing a more convenient control experience. The front-end working device has been optimized in design to ensure long-term stable operation, demonstrating outstanding durability and reliability.

In order to ensure that our quality can reassure and satisfy customers

We will conduct a detailed inspection of each excavator to ensure that each one is in good working condition. Before the machinery is dispatched, for each piece of equipment, we will replace the engine oil, hydraulic oil, gear oil, new air filter, oil filter, diesel filter, as well as the oil inlet/return/pilot/pipeline filter elements. Other damaged parts will also be replaced with new ones.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2. Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3. Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4. Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5. Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6. Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8. The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.

Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured