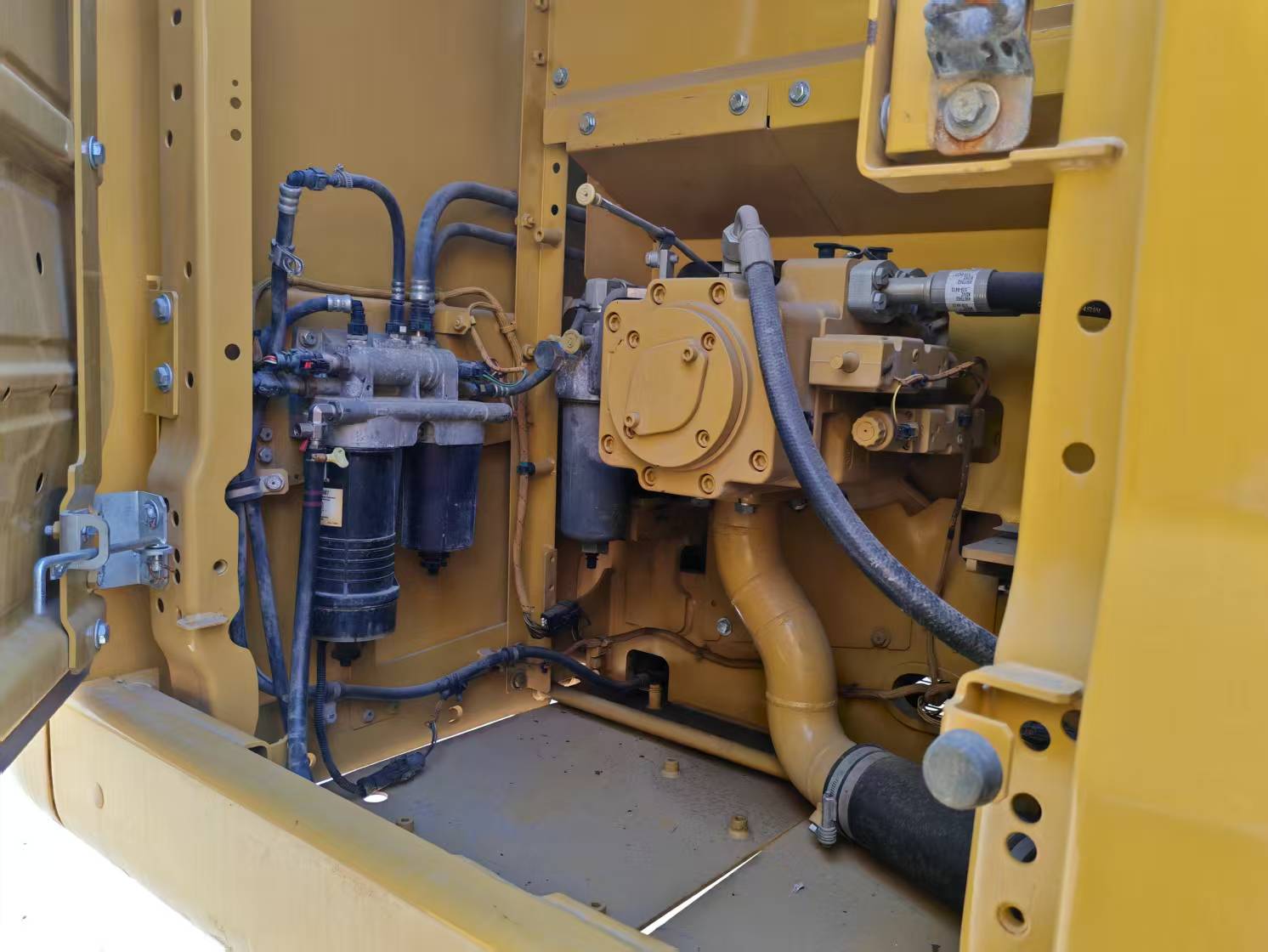

2021 Used CAT320D2L Excavator Earth Excavation For Peru.Dual pump hydraulic system:Equipped with a maximum total flow rate of 494 L/min, it provides strong excavation force and smooth composite action.

About CAT 320D2L Excavator

Description

This is a Caterpillar 320D2L excavator.Like the vast majority of construction machinery, it has also experienced the pain of a slowdown in economic growth. It was discovered and brought back by our engineers. When this excavator first arrived at our factory, there were quite a few scratches on the outer paint surface. However, the engine system, hydraulic system, electrical system, traveling system, cooling and intake system are all in good condition. After arriving at our factory, our engineers reinspected it, replaced the vulnerable parts and repainted them. Make it look as good as new.

2021 Used CAT 320D2L Crawler Excavator Specificaion

Engine model: C7.1 ACERT ™

Net power: 129 kW (approximately 173 horsepower)

Standard configuration: 25765-28230 kg (including 600mm track shoes)|

Main pump flow rate: 494 L/min (total of dual pumps)

Maximum working pressure: 35 MPa (equipment)/24.5 MPa (rotary)

Bucket capacity range: 1.33m ³

Maximum traction force: 227 kN

Rotation torque: 73.4 kN · m

Transport length: 10050 mm

Transport width (600mm track): 3190mm

Ground clearance: 440 mm

Performance characteristics

Equipped with C7.1 ACERT ™ Electronic control engine, constant engine speed control technology: automatically adjusts fuel pressure and hydraulic flow to adapt to different loads, balancing high productivity and low fuel consumption. Electric oil injection pump: improves starting speed and is easy to maintain. Dual pump hydraulic system: With a maximum total flow rate of 494 L/min, it provides strong excavation force and smooth composite action.

In order to ensure that our quality can reassure and satisfy customers.We will conduct a detailed inspection of each excavator to ensure that each one is in good working condition. Before the machinery is dispatched, for each piece of equipment, we will replace the engine oil, hydraulic oil, gear oil, new air filter, oil filter, diesel filter, as well as the oil inlet/return/pilot/pipeline filter elements. Other damaged parts will also be replaced with new ones.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2. Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3. Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4. Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5. Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6. Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8. The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured