This is a second-hand Doosan 225 excavator from 2020. It has good performance and a relatively new appearance, and is suitable for Latin American countries

This is a 225LC-9C type excavator produced by Doosan Company in 2020. It was used for excavation work at construction sites and had a working duration of 5600 hours. Although this machine has worked for a long time, thanks to the excellent working conditions of the original machine and the proper maintenance by the original owner, it still maintains a good working condition. Later, our factory engineers carried out maintenance on it and replaced some components to make it look like a brand-new vehicle. It is inexpensive and has an extremely high cost performance! It is particularly suitable for customers with limited budgets, allowing them to maximize their profits.

Equipment Model: DX225LC-9C

Code Name: 225

Type Excavator Excavator Tonnage (tons): 21.8

Purpose: Mining

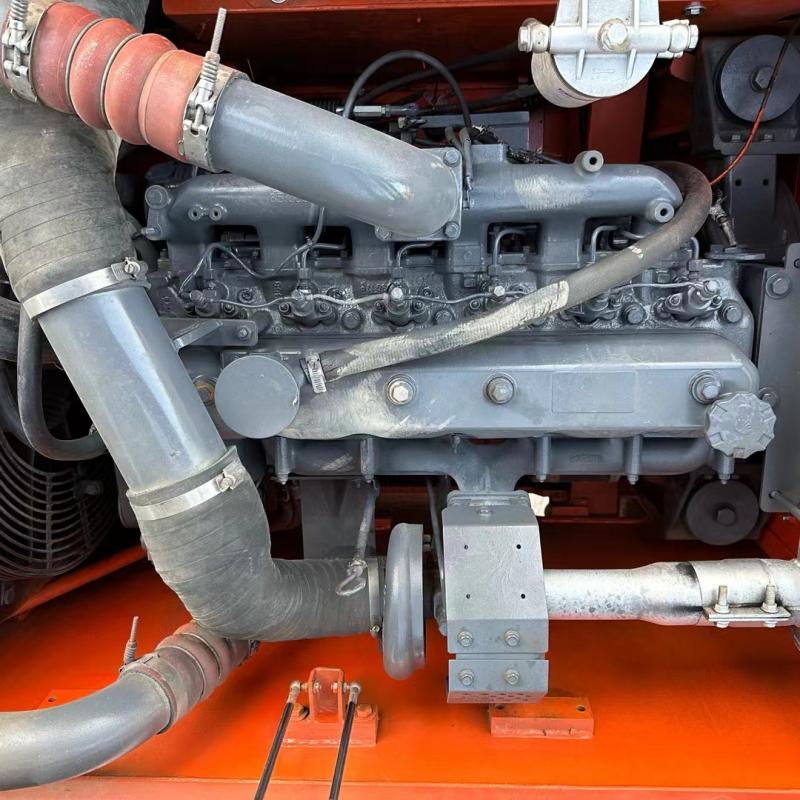

Type Engine Model: DL06

Engine Type: Inline Turbocharged

Engine Rated Power (kW): 115

Engine Speed (RPM): 1900

Total Engine Displacement (liters): 5.890

Engine Cylinder Number (units): 6 Piston Diameter × Stroke (mm): 100 × 125

Working Weight (kg): 21800

Scoop Capacity (cubic meters): 1.05

Travel Speed (High/Slow) (km/h): 5.7/3.1

Revolutions per Minute (RPM): 10.5

Ground Pressure Ratio (kPa): 44

Scoop Excavation Force (kN): 152

Balance Arm Excavation Force (kN): 108

Boom Length (mm): 5700

Handle Length (mm): 2900

Overall Size: Length × Width × Height (mm) in transportation state 9506 × 2990 × 3005 Minimum Turning Radius (Front End Device) (mm): 3560

Rear Wheel Turning Radius (mm): 2794

Maximum Excavation Radius (mm): 9873

Parking Surface Maximum Excavation Radius (mm): 9699

Maximum Excavation Depth (mm): 6592

Maximum Excavation Height (mm): 9616

Maximum Discharge Height (mm): 6830

Maximum Vertical Excavation Depth (mm): 3929

Fuel Tank (liters): 400

Hydraulic Fuel Tank (liters): 195

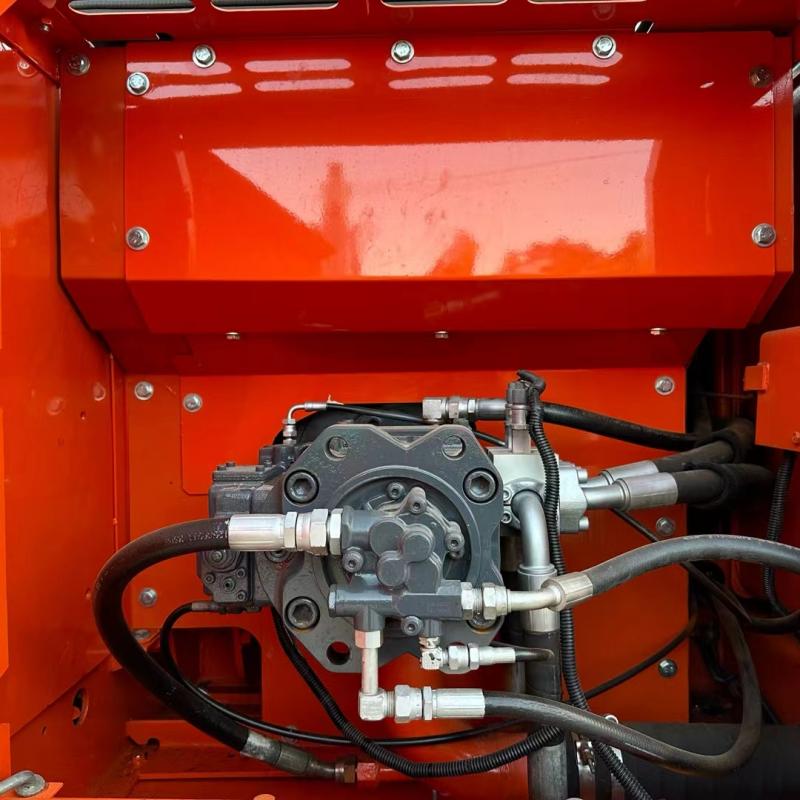

Equipped with the original Korean Doosan engine, it has strong and abundant power, capable of handling various working scenarios and improving work efficiency. In some large earthwork projects, mining operations, and other situations, it can efficiently complete excavation, loading, and other tasks. With the new hydraulic system, its movements are smooth and stable, providing excellent control and operation performance, reducing vibration and shaking during the movement of the excavator, and improving work stability. During excavation, rotation, etc., the equipment can maintain stable operation. With the original Doosan efficient engine, its fuel economy is excellent, reducing fuel consumption, saving energy costs, and lowering operating costs. Through the use of high-quality materials and strict production processes, the reliability and durability of the product are ensured, reducing the failure rate, extending the service life of the excavator, and reducing the frequency of maintenance and equipment replacement.

To ensure that our product quality can meet the expectations of customers, we will conduct detailed inspections on each excavator to ensure it is in good working condition. Inspection items and requirements are as follows:

Appearance and structure inspection requirements: Check if the boom and boom frame have welding defects or cracks (this is a sign of refurbishment);

Engine system inspection requirements: The engine exhaust should be normal, without abnormal noise, no blue smoke, no carbon deposits in the exhaust pipe, no oil leakage in the oil pan, no noise at idle speed.

Requirements for hydraulic system inspection: The hydraulic pump/motor should show no vibration, no cracks, and no oil leakage. The pressure should be stable. The chrome coating of the cylinder should have no scratches or oil leakage. The operation should be smooth. The pipeline should be confirmed to have no bulges or aging phenomena.

Requirements for electrical system inspection: The computer board should be able to display speed, pressure and fault codes normally. Wiring connection: The lighting, air conditioning and alarm systems should be able to operate normally.

Requirements for transportation system inspection: Track: The rubber layer should have no cracks, the chain guide rail should have slight wear, and the number of chains should match the machine. Motor: The rotational speed on both sides should be consistent during transportation, and the transportation should be normal.

Requirements for cooling and intake system inspection: The radiator should remain clean and free of dust, and the fan belt should not be loose. The list of easily damaged parts that must be replaced before mechanical transportation: Replace new engine oil, hydraulic oil and gear oil; replace new air filter, oil filter and diesel filter; replace intake/exhaust/pilot/pipeline filter elements; other damaged parts will also be replaced with new ones.

List of vulnerable components that must be replaced before mechanical transportation: Replace with new engine oil, hydraulic oil, and gear oil; replace with new air filter, oil filter, and diesel filter; replace the intake/exhaust/pilot/pipeline filter elements; and other damaged components will also be replaced with new ones.

RIZHAO BLAZERS INTERNATIONAL CO., Ltd. With 16 years of experience in the used construction machinery industry, we boast a comprehensive inventory of used construction equipment, including tractor truck, dump trucks, excavators, cranes, loaders, graders and other high-quality used construction machinery. We offer products from top brands such as Sinotruk, CAT, Komatsu, Hitachi and Doosan....[ Read More >>]

Contact Person : Miss Cathy

Tel & Fax : +86 13863351416

WhatsAp : +86 13863351416

E-mail : blazers02@163.com

Contact Person : Miss Jay

Tel & Fax : +86 19036371776

WhatsApp : +86 19036371776

E-mail : blazers03@163.com

Add: No.1000 Shandong Road,Donggang

District, Rizhao City, Shandong, China