2019 Used CAT312D2GC excavator is suitable for construction in Ghana.

Equipped with Caterpillar C9 ACERT ™ The engine power reaches up to 193kW, with high output power, high combustion efficiency, and abundant power, which can enable the excavator to operate stably in complex working conditions, providing strong excavation and bulldozing capabilities.

About CAT312D2GC Excavator

Description

This is a 2019 Caterpillar 312D2GC excavator, equipped with a Caterpillar C9 ACERT™ engine, delivering a power output of up to 193kW. It is highly powerful and enables the excavator to operate stably in complex working conditions. It is suitable for foundation construction of roads and bridges, land reclamation, as well as excavation and loading operations in small-scale mines or quarries. The vehicle is in excellent condition.

2019 Used CAT312D2GC excavator specificaion

Brand: Cat

Model abbreviation: 312D2GC

Excavator tonnage (t): 12.5

Engine model: 3054C

Rated power (kW): 56

Rated speed (r/min): not mentioned

Maximum torque (N · m): not mentioned

Total displacement (L): 4.4

Cylinder diameter x stroke (mm): 105 x 127

Engine brand: Caterpillar C9 ACERT ™

Working weight (kg): 12500

Bucket capacity (m ³): not mentioned

Walking speed (high/low) (km/h): 5.1

Rotation speed (rpm): 11.2

Fuel tank (L): 250

Hydraulic oil tank (L): 91

Engine oil change quantity (L): 16

Coolant (L): 18

Performance

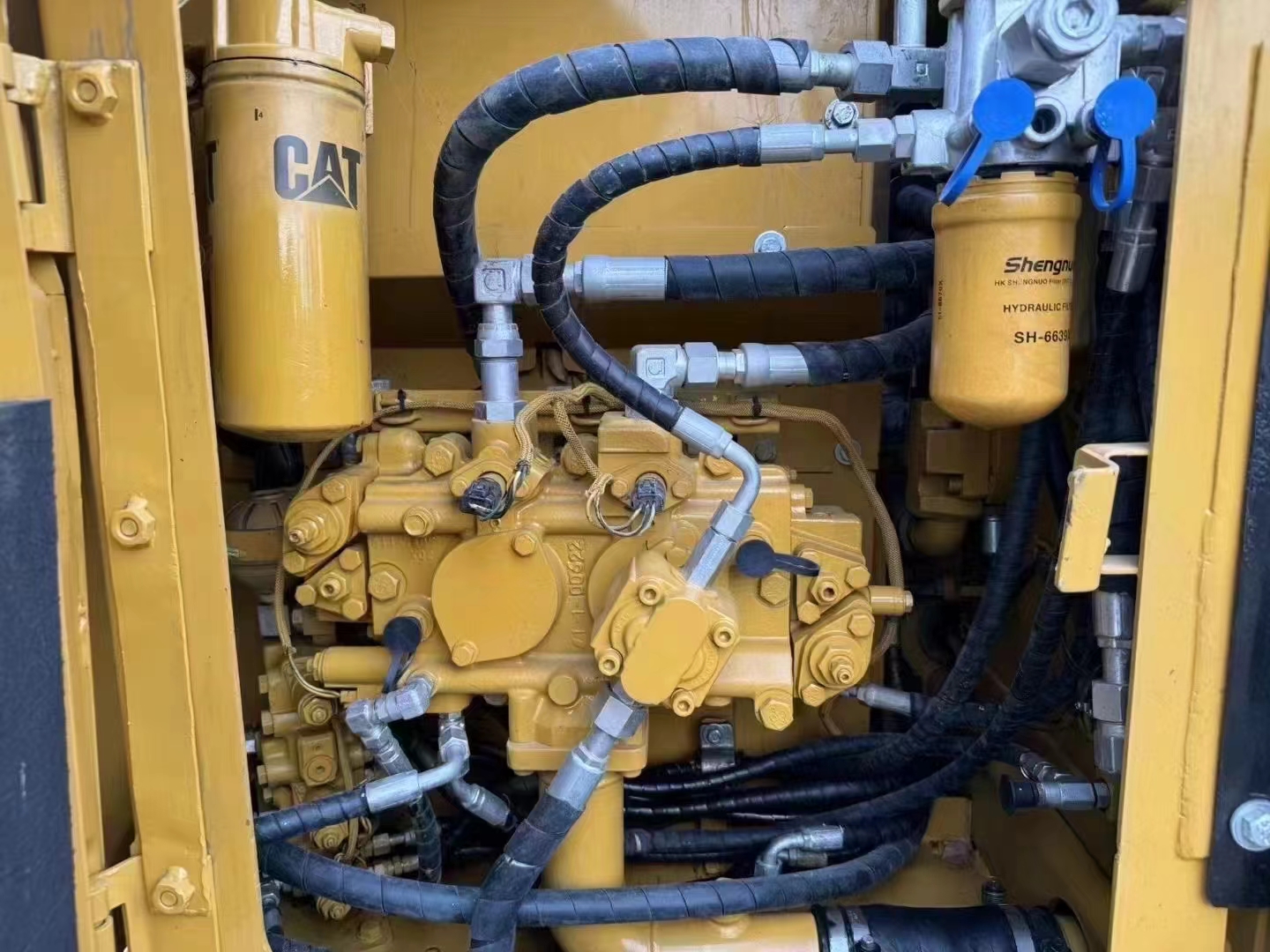

Equipped with Caterpillar C9 ACERT ™ The engine power reaches up to 193kW, with high output power, high combustion efficiency, and abundant power, which can enable the excavator to operate stably in complex working conditions, providing strong excavation and bulldozing capabilities. It adopts advanced hydraulic system, with more stable flow and pressure output, and can quickly and accurately control various working devices, improving work efficiency and reducing energy consumption. Adopting high-strength materials and advanced welding technology, the whole machine structure is sturdy and durable, equipped with a hard material excavation device, and has excellent wear resistance. After strict quality control and experimental verification, it has high reliability, long service life, and can maintain stable working performance in various harsh working environments. The mechanical structure is simple, easy to maintain, and daily maintenance can be completed in a short period of time, which can reduce downtime and improve work efficiency. The oil system is equipped with filters and oil bath offline high-efficiency filters, which can extend the service life of hydraulic oil and reduce maintenance frequency.

In order to ensure that our quality can reassure and satisfy customers.

We will conduct a detailed inspection of each excavator to ensure that each one is in good working condition. Before the machinery is dispatched, for each piece of equipment, we will replace the engine oil, hydraulic oil, gear oil, new air filter, oil filter, diesel filter, as well as the oil inlet/return/pilot/pipeline filter elements. Other damaged parts will also be replaced with new ones.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2. Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3. Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4. Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5. Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6. Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8. The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured.