This is a volvo excavator produced in 2021, mainly used for digging ditches and suitable for Guatemala.The maximum excavation radius is 10700mm, the maximum excavation depth is 7300mm, and the maximum excavation height is 1500mm, which can meet the operational needs of various complex projects and can play a role in different site conditions.

About Volvo EC290

Description

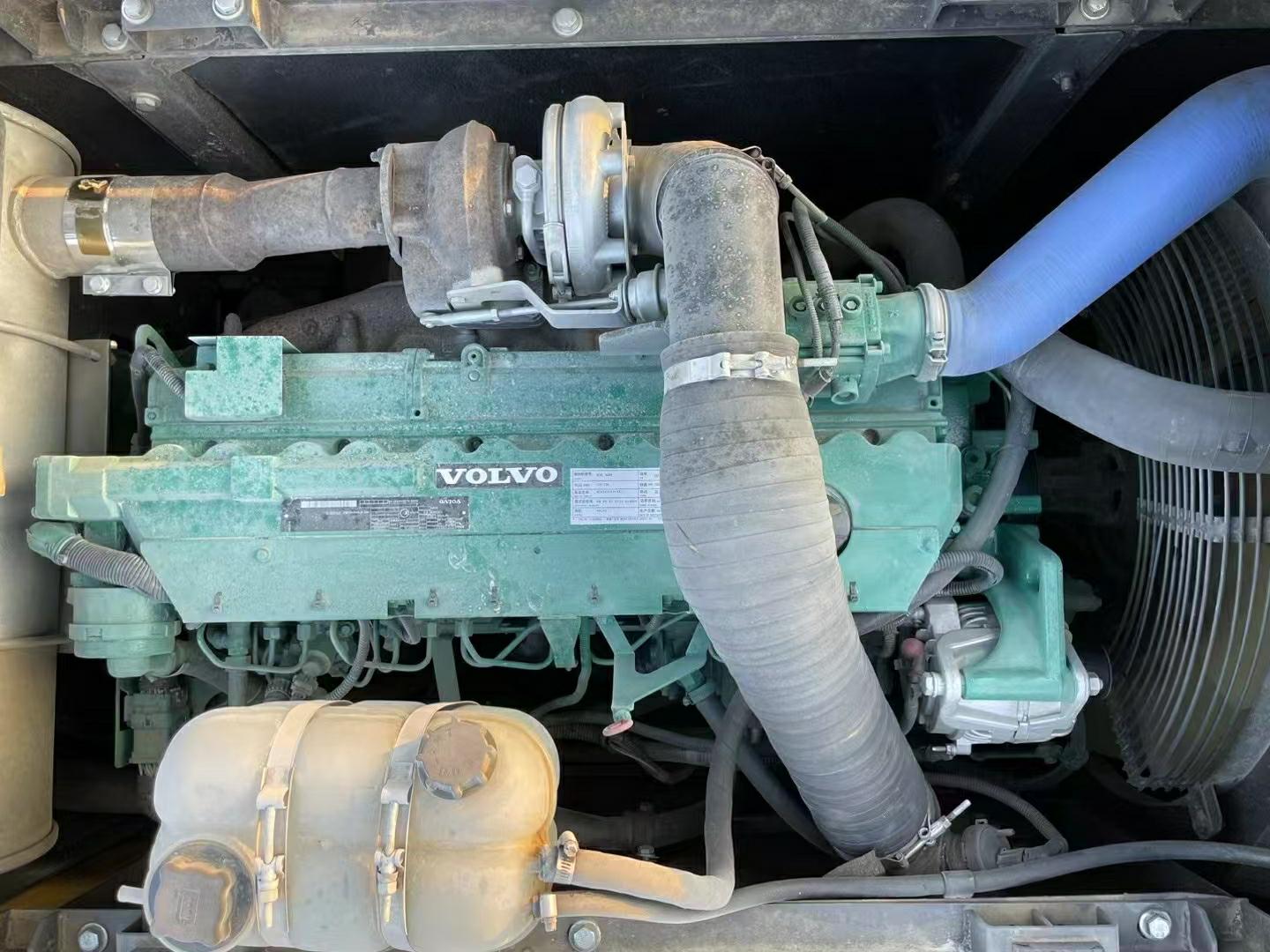

The production year of this Volvo EC290 excavator is 2021. The owner of the excavator originally planned that after the epidemic ended, China would need a large number of engineering projects. However, he never expected that the rapid economic growth after the epidemic ended would only last for one year before slowing down sharply. A large number of construction sites were shut down. In order to recover funds, the original owner had no choice but to sell the machine. The condition and quality of the machine, with slight wear marks on each component, and a working time of only 2,600 hours Later, our factory carried out surface treatment on the machine, and the treated machine was in a nearly new state.

Volvo EC290 Crawler Excavator Specificaion

Equipment model: EC290

Excavator tonnage (tons): 29

Engine model: Volvo D7D

Rated power (kilowatts): 143

Rated speed (revolutions per minute): 1900

Overall working weight (kilograms): 29000

Standard bucket capacity (cubic meters): 0.95 - 2.1

Bucket digging force (kilonewtons): 198.4

Maximum digging radius of the working Range (millimeters): 10700

Maximum digging depth (millimeters): 7300

Maximum digging height (millimeters): 150

Maximum excavation height (mm):1500

Performance characteristics

The engine has strong power and is equipped with a Volvo D7D engine, with a rated power of 143 kW and a rated speed of 1900 r/min. It can provide stable and sufficient power support for various operations of the excavator, ensuring efficient operation under different working conditions. The digging force of the bucket is as high as 198.4kN, which can easily handle various types of soil and materials during excavation operations, improve excavation efficiency, and reduce operation time. The maximum excavation radius is 10700mm, the maximum excavation depth is 7300mm, and the maximum excavation height is 1500mm, which can meet the operational needs of various complex projects and can play a role in different site conditions.

In order to ensure that our quality can reassure and satisfy customers

We will conduct a detailed inspection of each excavator to ensure that each one is in good working condition. Before the machinery is dispatched, for each piece of equipment, we will replace the engine oil, hydraulic oil, gear oil, new air filter, oil filter, diesel filter, as well as the oil inlet/return/pilot/pipeline filter elements. Other damaged parts will also be replaced with new ones

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2. Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3. Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4. Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5. Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6. Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8. The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.

Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured