The XCMG XS263H is a 26-ton single-drum roller with vibratory force exceeding 400kN, delivering outstanding compaction efficiency. Equipped with a China III emission-compliant diesel engine, it features powerful performance, fuel-efficient operation, stable control, and easy maintenance.

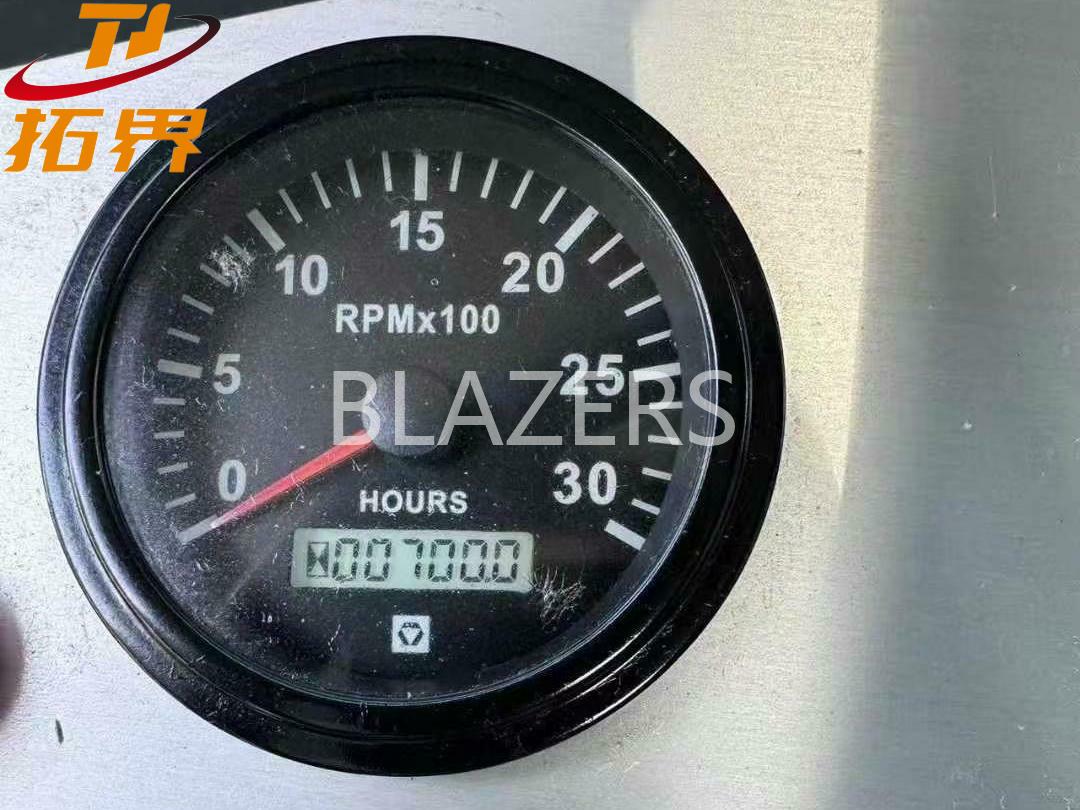

This XCMG XS263 roller, recently retired, features electronic transmission, imported hydraulic pump, and a Shangchai engine, with only 700 operating hours. Over the past decade, it served as backup equipment, deployed only briefly for critical projects to minimize usage frequency, resulting in exceptionally low operating hours. Benefiting from regular maintenance, superior storage conditions, and the high durability of its imported components, the roller remains in like-new condition with a smoothly running engine, akin to a dormant treasure awaiting rediscovery.

When a piece of equipment comes into our hands, it never undergoes a one-size-fits-all refurbishment process. We listen to your specific needs: Are you pursuing original factory specifications, or reinforcements tailored for particular working conditions? What appearance standards must be achieved? What is your budget range? Our engineering team then crafts a bespoke refurbishment plan exclusively for you.

The XCMG XS263H Specificaion

Model: XS263H

Operating Hours: 700 hours

Operating Weight: 26000kg

Machine Operating Weight: 26000kg

Engine Model: SC7H200G3

Overall Dimensions (L×W×H): 6530mm × 2470mm × 3260mm

Wheelbase: 3330mm

Drum Diameter: 1600mm

Drum Width: 2170mm

Front Axle Distribution Weight: 13000kg

Rated Power: 147kW

Daily Maintenance Checklist for Road Roller

Check Fluid Levels & Fuel

Inspect engine oil, hydraulic oil, transmission oil, and coolant levels (using dipstick or sight glass); fuel tank level. In hot weather (like current summer), coolant inspection is particularly critical to prevent engine overheating and shutdown.

Inspect Filters & Air Intake System

Check the cleanliness of air filter, fuel filter, and hydraulic oil filter; inspect air intake system for blockages. Lightly tap the air filter to remove dust (replace if severely dirty); ensure the filter element is undamaged. This step prevents contaminants from entering the engine, reducing 80% of early wear risk. At dusty construction sites (e.g., roadwork), daily air filter cleaning significantly enhances equipment efficiency.