Single-steel-wheel pavers are suitable for soil compaction and construction in narrow spaces, and are suitable for base layer or maintenance scenarios.

About ShangTui SR20M

Narrate

The Shangpeng SR20M road roller is centered on an ultra-heavy mechanical vibration system, equipped with a dual vibration system, which provides efficient and uniform compaction capabilities for non-clayey soil and concrete materials. Its power system adopts a highly reliable configuration, with balanced fuel economy and performance, and is suitable for high-intensity working environments. The vibration wheel structure has been optimized, combining excitation force and durability, ensuring stable long-term output in large-scale infrastructure projects. From highways to mines, from dams to industrial sites, it interprets the industrial aesthetics of "functionality and cost-effectiveness" with its solid operational performance.

In the field of second-hand equipment exports, we always engrave "quality" into the genes of every choice and service. Every piece of equipment we select undergoes strict testing and in-depth maintenance to ensure that it remains stable in performance and durability when delivered to you - compared to short-term price fluctuations, what we care more about is your peace of mind when using it: reducing the loss from equipment failures and lowering the cost of subsequent maintenance. These "long-term values" hidden in quality are the most solid foundation for cooperation.

20-ton ShangTui SR20M single-wheel road roller Specificaion

Model: SR20M (Mechanically Driven Single-drum Vibratory Roller)

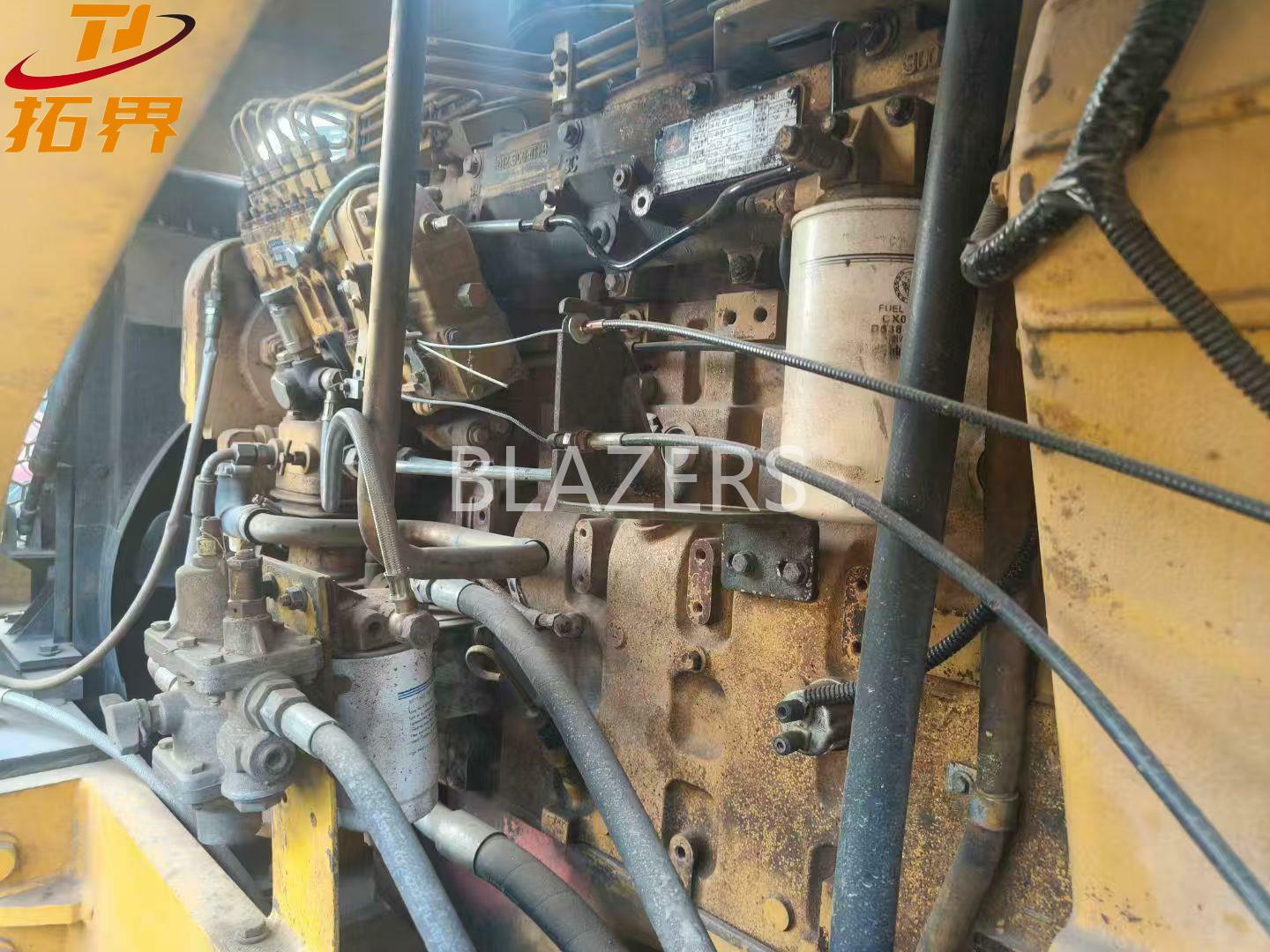

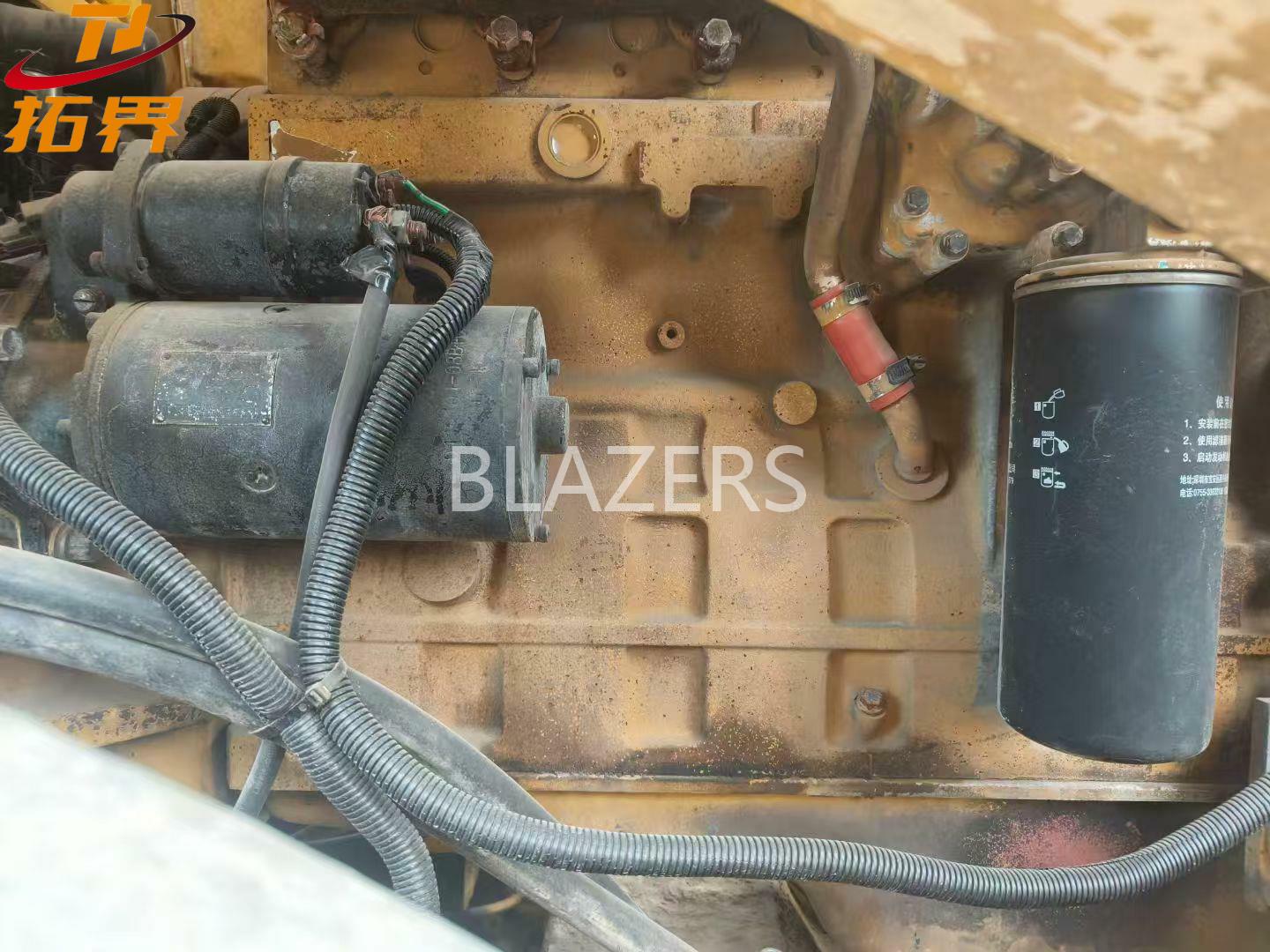

Engine Model: Cummins 6BTA5.9-C180 (China III Emission)

Rated Power: 132 kW @ 2200 rpm

Peak Torque: 720 N·m @ 1500 rpm

Cooling System: Forced Water Cooling + Turbocharging

Operating Mass: 20-ton class (Drum mass ≈13 tons)

Vibration Frequency: 28/35 Hz (Dual-frequency adjustable)

Amplitude: 1.8/0.9 mm (Dual-amplitude auto-switching)

Max. Excitation Force: 380 kN (at 35Hz)

Gradeability: ≥40%

Drum Dimensions: 1600 mm × 2170 mm (Width)

Min. Turning Radius: ≤6.2 m

Fuel Tank Capacity: 235 L

Hydraulic Oil Tank Capacity: 120 L

Daily Maintenance Checklist for Road Roller

1. Check Fluid Levels & Fuel

Inspect engine oil, hydraulic oil, transmission oil, and coolant levels (using dipstick or sight glass); fuel tank level. In hot weather (like current summer), coolant inspection is particularly critical to prevent engine overheating and shutdown.

2. Inspect Filters & Air Intake System

Check the cleanliness of air filter, fuel filter, and hydraulic oil filter; inspect air intake system for blockages. Lightly tap the air filter to remove dust (replace if severely dirty); ensure the filter element is undamaged. This step prevents contaminants from entering the engine, reducing 80% of early wear risk. At dusty construction sites (e.g., roadwork), daily air filter cleaning significantly enhances equipment efficiency.

3. Inspect Ground Contact Components & Brakes

Check tire/steel wheel pressure and wear (using tire pressure gauge); brake fluid level and braking performance (test by pedal depression); tightness of steel wheel or tire bolts. Daily inspections identify potential issues (e.g., loose bolts), preventing downtime repair costs.

4. Clean Machine & Check Fasteners

Remove mud, asphalt residue, and water stains from the roller’s surface; inspect critical fasteners (e.g., engine mounts, roller connection bolts). Clean with a soft brush or low-pressure water jet to avoid damaging electrical components. Post-cleaning, a tidy appearance improves heat dissipation. During rainy seasons, cleaning prevents corrosion, extending equipment life by 5+ years.

5. Operational Test

Start the equipment; check dashboard indicators (e.g., oil pressure, battery voltage); listen for abnormal noises/vibrations; test steering and compaction functions. Limit runtime to 2–3 minutes; stop immediately for troubleshooting if warning lights activate. Daily tests enable early fault detection (e.g., hydraulic system noise), reducing 30% of unexpected repair costs.