About Hitachi Zx350

Description

This is a Hitachi Zx350 general-purpose excavator that has been refurbished according to customer requirements. This is the condition after the refurbishment. The Hitachi Zx350 excavator is equipped with an efficient engine and hydraulic system, which enables the machine to have greater digging force and faster operation cycle time. The sturdy chassis features durable guide wheels, large-diameter rollers and thick-toothed sprockets. The track links are more durable and have a longer service life.

Specificaion

Engine Model: Isuzu 6HK1X

Engine Type: 4 - cycle water - cooled, common rail direct injection

Rated Power: 210 kW (at 1900 min⁻¹)

Maximum Torque: 1080 N·m (at 1500 min⁻¹)

Operating Weight: 35200 - 37500 kg

Bucket Capacity: 1.15 - 1.86 m³

Bucket Digging Force: 246 kN

Arm Crowd Force: 185 - 222 kN

Maximum Digging Reach: 10570 - 11220 mm

Maximum Digging Depth: 6360 - 7380 mm

Maximum Dumping Height: 6940 - 9230 mm

Undercarriage Length: 4970 mm

Undercarriage Width: 2990 - 3190 mm

Overall Width of Upper Structure: 2990 mm

Overall Height of Cab: 3150 mm

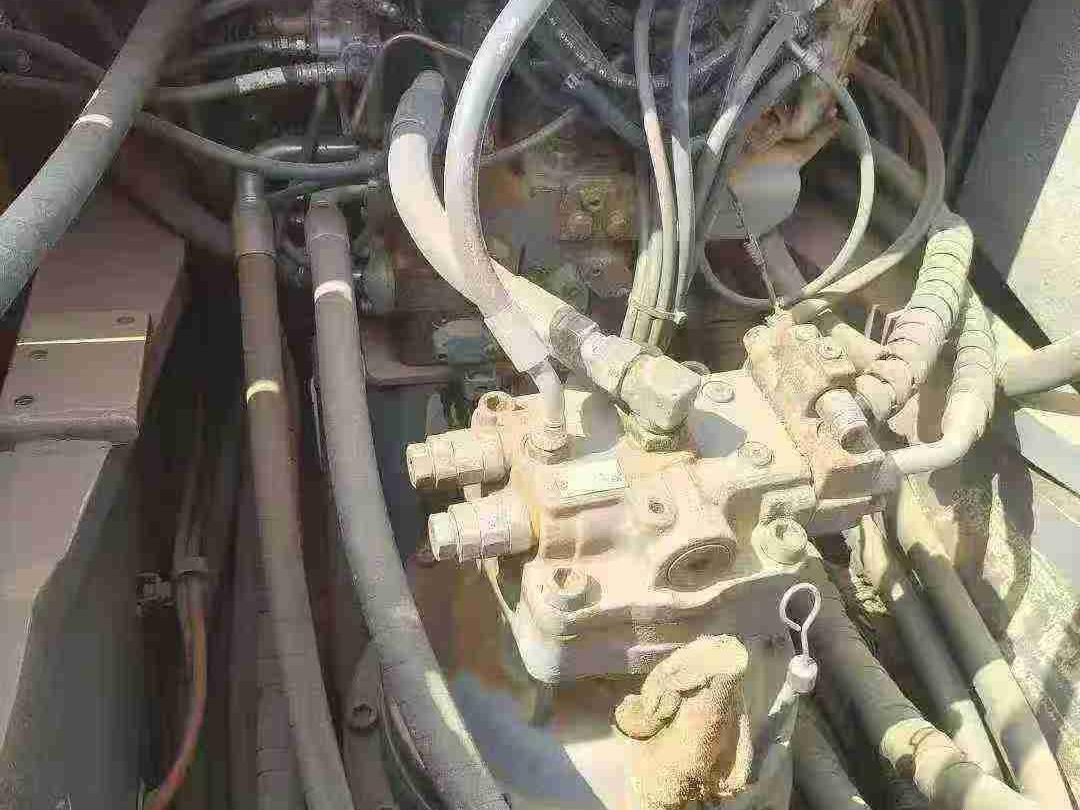

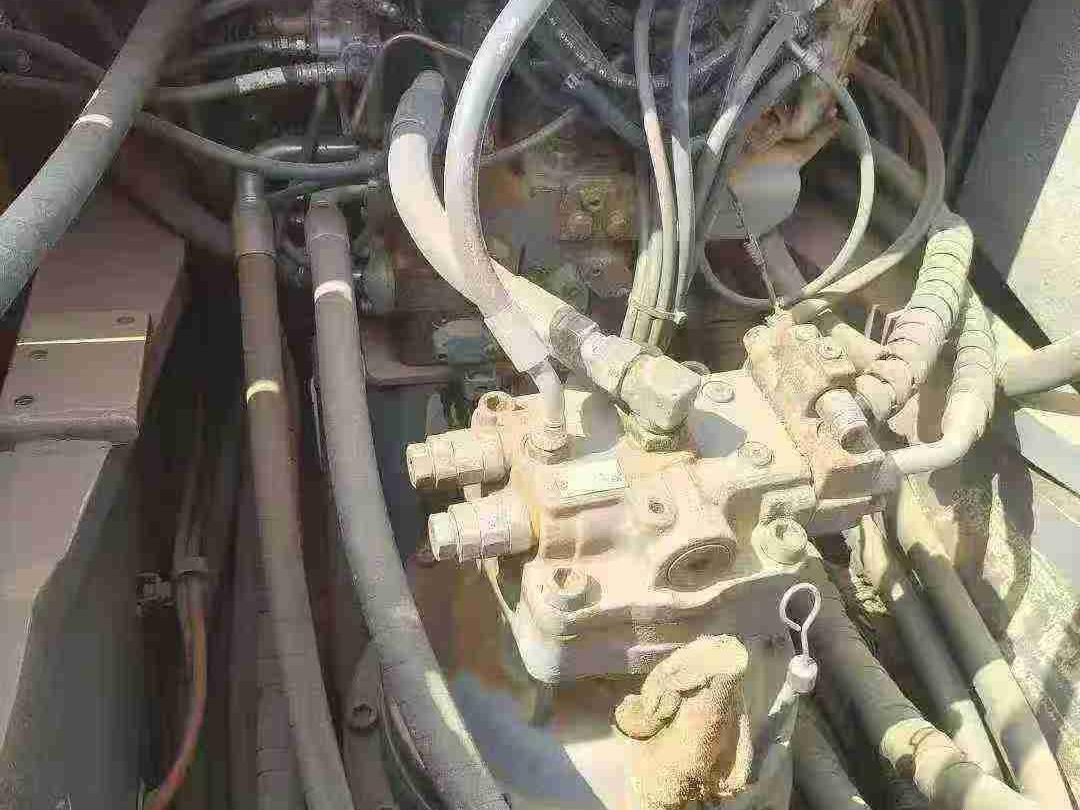

Excavator Detail Picture

Used Excavator Shipment Information

The second-hand construction machinery equipment we utilize can be transported via Roll-on/Roll-off vessels (Ro-Ro ships), bulk carriers, and flat rack container ships. Reference images illustrating the loading process are attached for your review.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2.Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3.Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4.Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5.Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6.Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8.The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.

Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured