The Hitachi ZX360H crawler excavator is a large - scale construction machinery, which is widely used in various engineering construction due to its powerful performance and reliability.

Abount Hitachi ZX360H-5A Crawler Excavator

Description

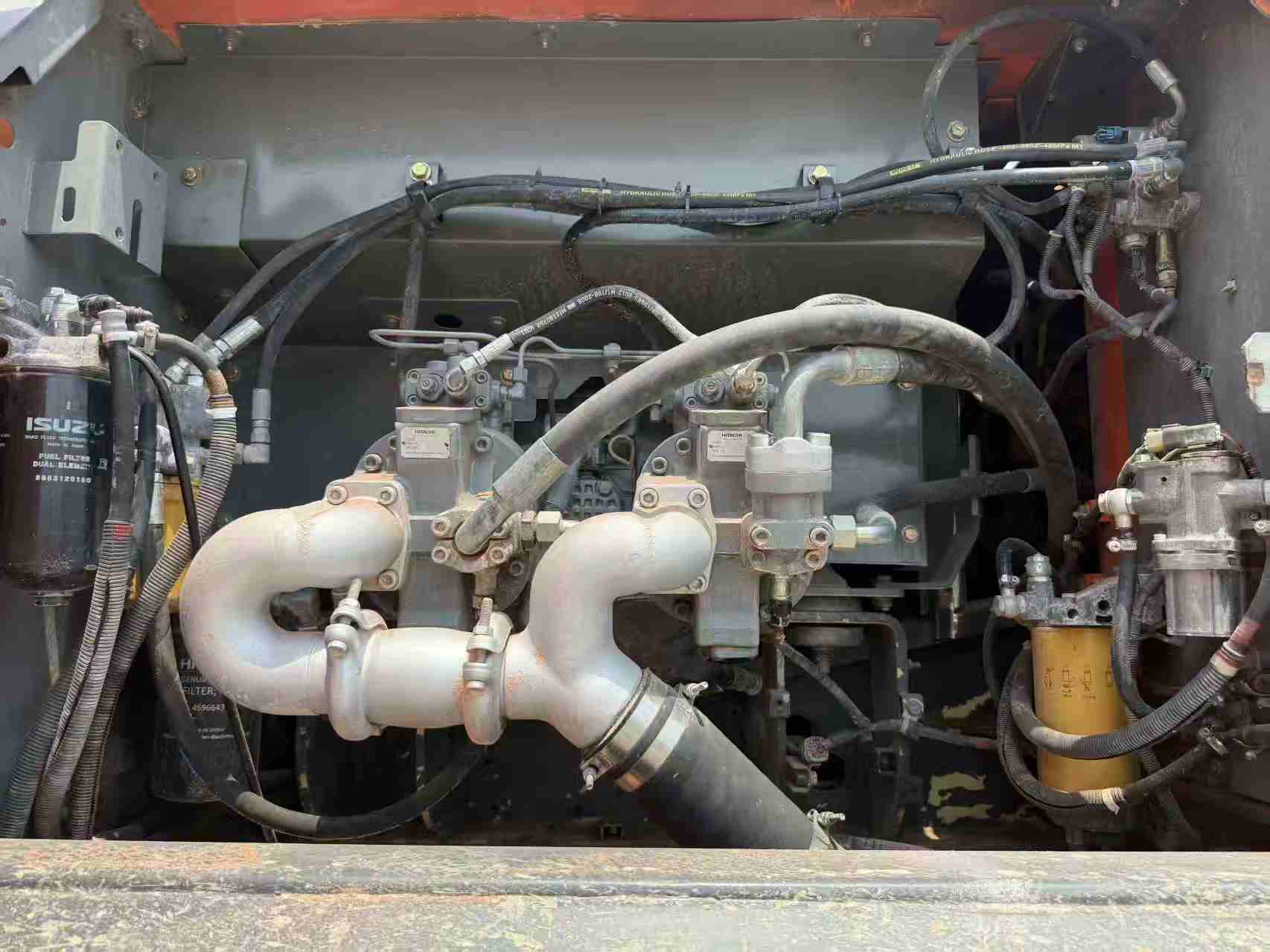

Equipped with Hitachi's advanced hydraulic technology, it can provide smooth and precise control, shorten the working cycle time, and improve the overall operation efficiency.

Hitachi ZX360H Specificaion

Basic Parameters

Operating Weight: Approximately 33,900 kg.

Bucket Capacity: Usually 1.6 m³ (rock - narrow bucket), and it can also be 1.6 - 1.8 m³ according to different models.

Engine Model: Isuzu ISUZU AH - 6HK1XQA.

Rated Power: 184 kW/2000 rpm.

Displacement: 7.79 L.

Performance Parameters

Digging Force: The bucket digging force is 237 kN, and the arm digging force is 172 kN.

Travel Speed: 3.2/5.0 km/h.

Maximum Digging Radius: 11,100 mm.

Maximum Digging Depth: 7360 mm.

Maximum Digging Height: 10,250 mm.

Performance characteristic

Powerful Power System: Driven by an Isuzu engine, it adopts a direct - injection, turbo - charged, intercooled working mode, which has the advantages of high power and high fuel efficiency, and can easily cope with heavy - duty tasks.

Advanced Hydraulic System: Equipped with Hitachi's advanced hydraulic technology, it can provide smooth and precise control, shorten the working cycle time, and improve the overall operation efficiency.

Operator - friendly Cab Design: The cab is ergonomically designed, with a spacious interior, equipped with air - conditioning and adjustable seats, which can provide a comfortable working environment for operators. At the same time, it has good visibility, which is convenient for operators to observe the working conditions and improves work safety.

High - durability Structure: It is made of high - quality materials and components, and the key parts are strengthened, such as the thick - plate boom, the WC (tungsten carbide) spraying at the connection between the arm and the bucket, etc., which can withstand harsh working conditions and has a long service life.

Convenient Maintenance: The maintenance points are easy to access, and it is equipped with an intuitive diagnostic system, which is convenient for maintenance personnel to carry out maintenance and repair work, reducing machine downtime and ensuring that the equipment is in good working condition.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2.Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3.Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4.Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5.Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6.Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine. 7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

7.The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.

Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured