Wheel dozers are suitable for earthmoving operations requiring rapid transfer in construction, mining, etc., combining high efficiency and mobility.

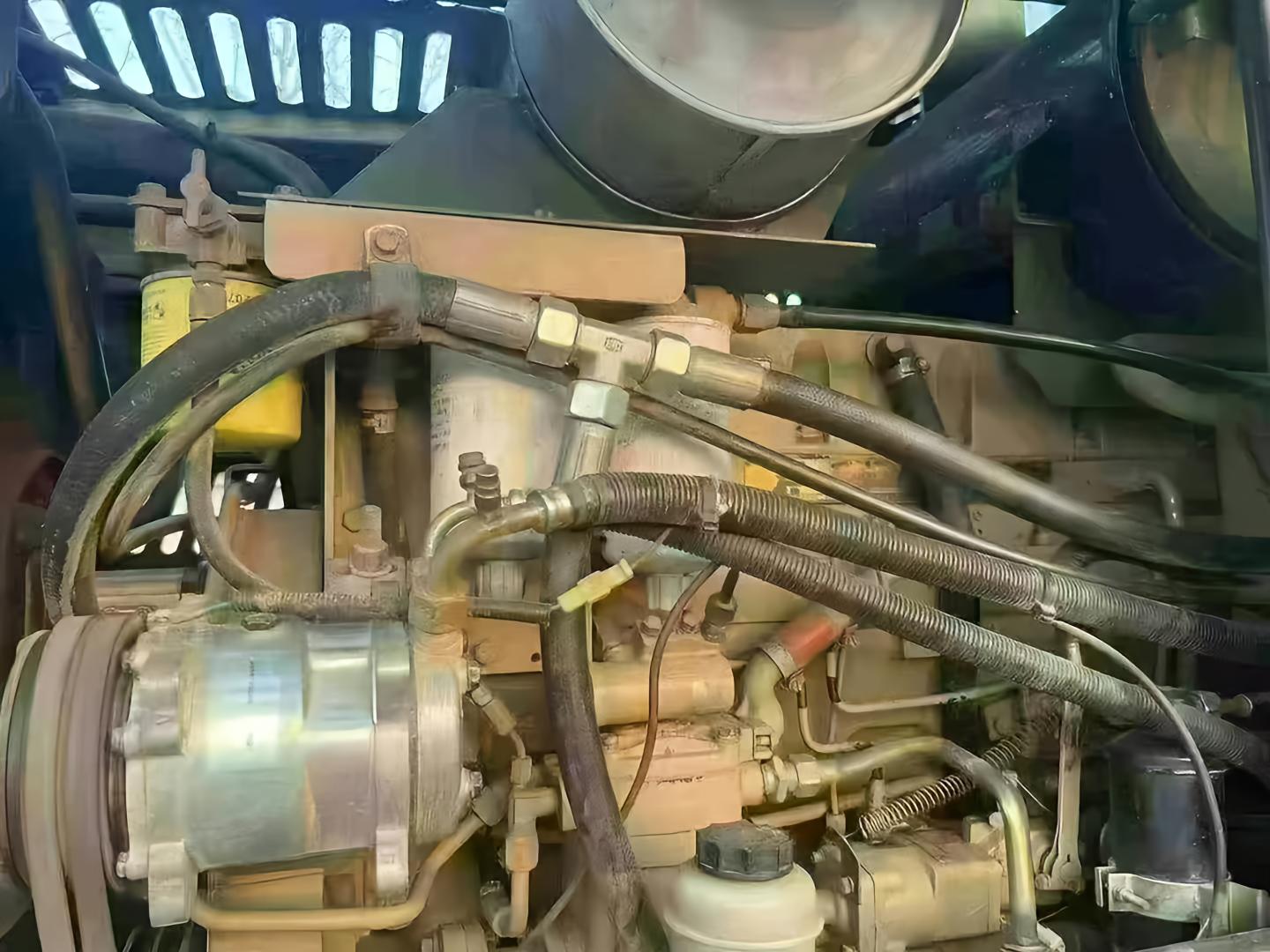

This is a YUTONG HEAVY INDUSTRY TLK220 wheel dozer, with a service history of ten years but only 700+ actual operating hours. Originally serving as a backup unit for its organization, it remained in static storage on standby and was deployed only for critical missions. Equipped with a Cummins 200+ horsepower engine, its 3.4-meter front blade features tilting functionality. The front scarf plate ensures superior stability, while the adjustable undercarriage adapts to varied terrains. The hydraulic system remains smooth to this day. Despite its age, the machine maintains excellent mechanical condition due to minimal usage, making it suitable for engineering scenarios demanding robust power and flexible operation

In this industry, the unwritten rule is concealment: covering cracks with fresh paint, hiding oil leaks with wooden boards, disguising structural flaws with temporary welds. We defy this convention—our warehouse floor forever bears oil stains of varying shades, where leaked hydraulic fluid from test runs speaks its truth; in the exhibition area, the bulldozer cabins stand with doors casually thrown open, exposing aged wiring harnesses and reinforced pedals. An engineer once called us "mechanical skinny-dippers," yet it is precisely this radical transparency that compels overseas buyers to conduct transoceanic video inspections

YUTONG HEAVY INDUSTRY TLK220 Detailed Specifications

Engine Model:Cummins M11-C225

Rated Power:225 hp

Transmission Type:Hydro-mechanical transmission

Drive Type: Wheel drive

Forward/Reverse Gears:3+3 gears

Maximum Speed: Approx. 25-30 km/h

Dozer Blade Type: Straight tilt blade

Blade Capacity: 3.4 m³

Maximum Blade Thrust: 100 kN

Operating Weight: 22 tons

Dimensions (L×W×H): 6800 mm × 2800 mm × 320

Daily Maintenance

1. Engine oil, hydraulic oil, coolant, and fuel level checks

Inspect levels and replenish to standard if insufficient; observe for leakage traces.

2. Air cleaner filter dust removal

Clean dust from air filter elements (require shift-based cleaning in dusty environments); check diesel filter water sedimentation and drain.

3. Undercarriage system maintenance

Adjust track tension to specified value (excessive looseness/tightness accelerates wear); remove rocks and mud between track plates; inspect lubrication status of idler wheels and carrier rollers.

4. Structural components and safety devices

Tighten blade and ripper connection bolts; check brake system and steering control sensitivity; ensure lights, horn, and fire extinguisher are functional.

5. Machine cleaning

After shutdown, remove debris from radiator grille and dirt from the machine body to prevent clogging and corrosion.