Operating Weight: 20,000 kg

Engine: Komatsu SAA6D107E-1

Rated Power: 110 kW / 148 HP @ 2000 rpm

Bucket Capacity: 0.8 – 1.0 m³

20-Ton Komatsu Crawler Excavator Features

The used Komatsu PC200-8 Hydraulic Excavator is an excellent choice for earthmoving, road construction, mining, and general construction works. This 20-ton class excavator combines power, durability, and fuel efficiency, making it one of the most popular models in the Komatsu range. It is equipped with a Komatsu SAA6D107E-1 engine that delivers 110 kW / 148 HP @ 2000 rpm, ensuring high productivity with low fuel consumption.

Description Parameter value

Rated Power: 110kW / 148hp

Operating Weight: 20,000 kg

Maximum Travel Speed: 5.5 km/h

Bucket Capacity: 1.0 m³

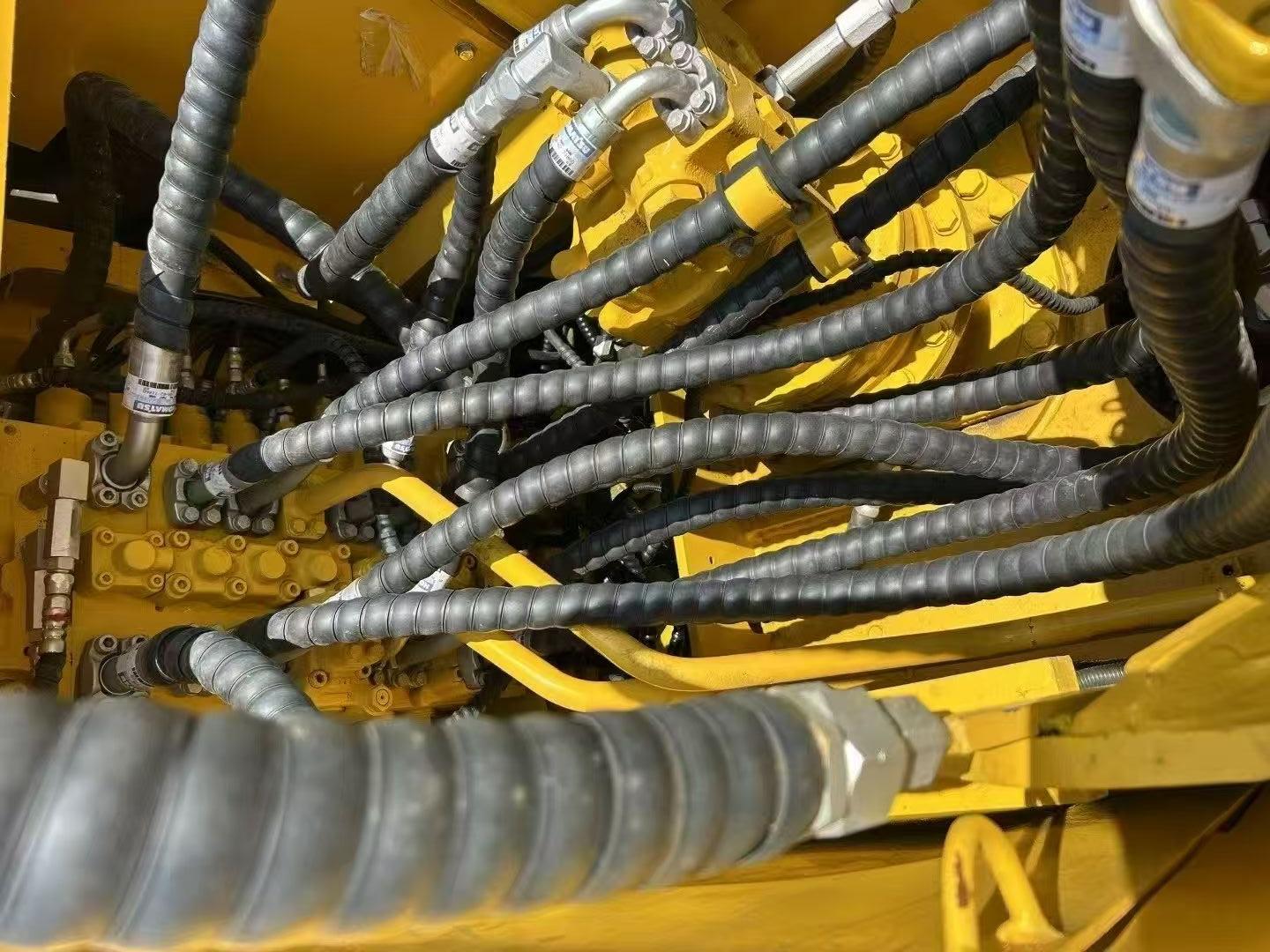

Hydraulic System Flow: 205 L/min

Swing Speed: 11.2 rpm

Maximum Gradeability: 70% / 35°

Ground Pressure: 41.8 kPa

20-Ton Komatsu crawler excavator specification only for your reference, we will recommend other model excavator basic your request.

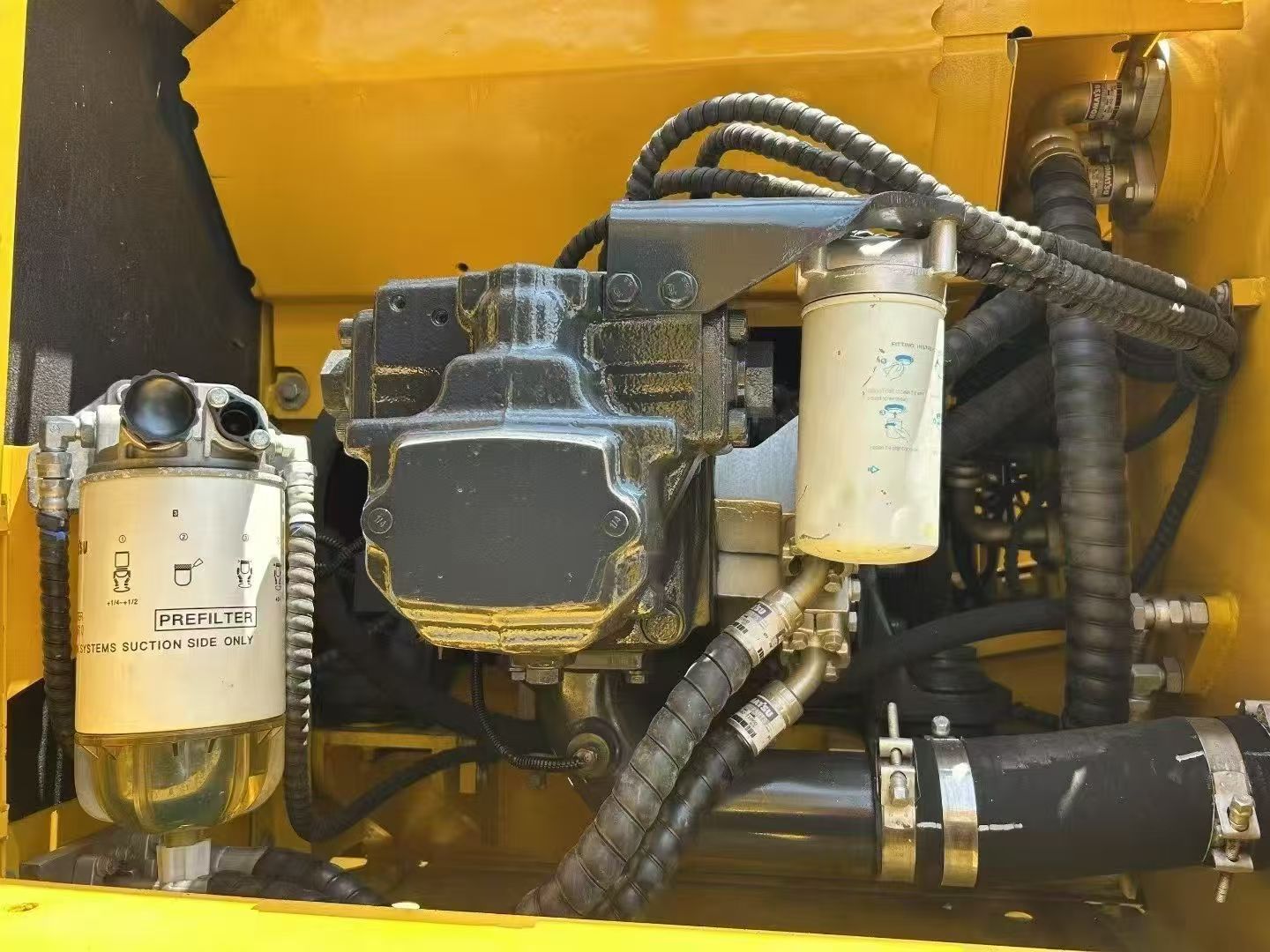

Excavator Detail Picture

Used Excavator Shipment Information

The second-hand construction machinery equipment we utilize can be transported via Roll-on/Roll-off vessels (Ro-Ro ships), bulk carriers, and flat rack container ships. Reference images illustrating the loading process are attached for your review.

Maintenance

1.Engine oil needs to be replaced regularly, with a general replacement cycle of 500 hours.

2.Hydraulic oil should be replaced according to the prescribed maintenance cycle, which is 2,500 to 3,000 hours.

3.Timely addition of lubricating grease can effectively reduce the wear of each component and ensure smooth operation of all components.

4.Regularly clean or replace the air filter element and air filter to ensure that the engine sucks in clean air and improve fuel efficiency. In harsh working conditions such as heavy dust, the frequency of inspections should be increased.

5.Check the coolant level to keep the cooling system unobstructed and prevent overheating.

6.Clean the radiator. When an excavator is in operation, it generates a large amount of heat. The cleaning of the radiator is very important for maintaining the normal operation of the engine.

7. Tracks are important components of excavators. Appropriate track tension can extend the service life of tracks. Regularly inspect and adjust the tension of the tracks to ensure they are within a consistent standard range.

8.The transmission system is an important component of an excavator. Regular checks should be conducted on the transmission chain, gears and other parts, and severely worn components should be replaced in a timely manner.

Through the above daily maintenance measures, faults can be effectively prevented, the service life of excavators can be prolonged, and the safety and smooth progress of work can be ensured.

Contact Our Sales Team

Have questions or need a quote?

Reach out to me, Cathy, directly through the channels below:

Email: blazers02@163.com

WhatsApp: +86 190 6367 1196

I usually respond within 12 hours to ensure you get the information you need promptly.