The Caterpillar 320GC excavator is suitable for land grading, subgrade correction, and riverbed excavation tasks.

Amidst the flashy price wars and concealed refurbishment traps plaguing the second hand heavy machinery market, we stand unshaken by one ironclad principle Quality First, Integrity as Foundation. Today, we proudly present our curated range of pre owned excavators We abstain from cutthroat pricing because we believe exceptional machinery transcends cost it embodies safety, efficiency, and decade consistent reliability. Like your most trusted partner, we insist First witness the raw truth of the machine, then discuss post-inspection refinements each step designed to deliver unshakable confidence.

We profoundly understand that clients seek lasting value, not "cheap deals." While our second-hand excavators may carry a 10%-15% premium over competitors, they deliver greater long-term savings through

1. Durability Advantage

Core components maintained to OEM standards, extending service life by 40% eliminating costly frequent replacements.

2. Safety Commitment

We categorically reject flaw concealment. Example , For equipment with surface rust, we disclose it transparently and provide anti-corrosion solutions never cosmetic paint masking. This stems from our safety first ethos.Last year, a customer avoided a hydraulic system failure through our transparency. He said, "True quality is not on paper, but is forged in every excavation."

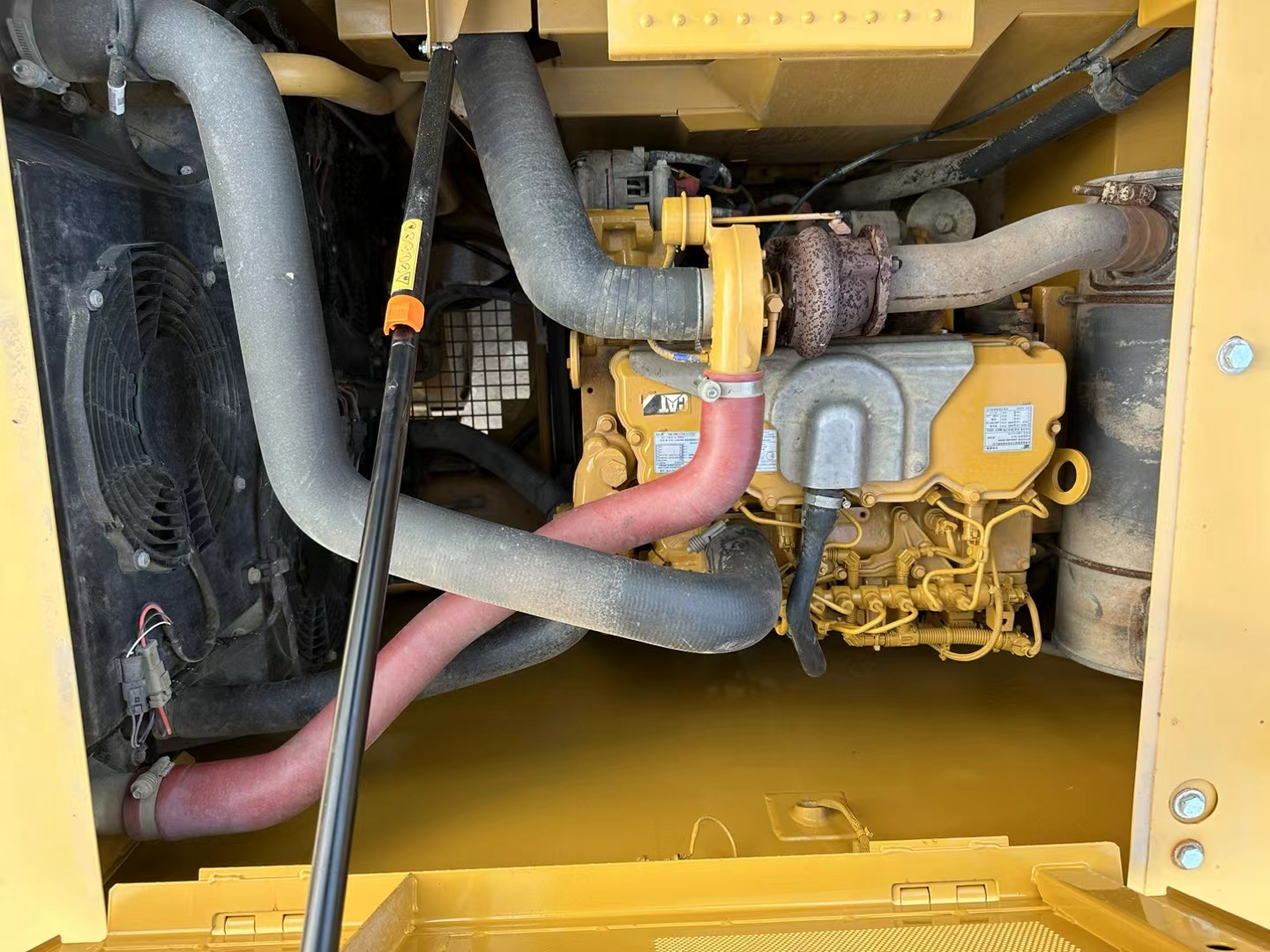

The used Caterpillar CAT320GC Specification

Engine:Cat C2.4

Net Power:107 kW / 143 HP

Main Pump Flow:2 × 127 L/min

Bucket Digging Force:103 kN

Arm Digging Force:76 kN

Operating Weight:19,900 kg

Transport Dimensions:9.35 m × 2.55 m × 2.95 m

Bucket Capacity Range:0.28–1.26 m³

Max. Digging Depth:6,430 mm

Max. Dumping Height: 6,620 mm

Gradeability:70%

Shipping Information for Second-Hand Construction Machinery

Our used construction equipment can be shipped via Ro Ro vessels , bulk carriers, and flat rack container ships. Reference photos of loading procedures are attached for your review.

Maintenance Guidelines

1. Engine Oil Replacement

Requires regular changes at 500 operating-hour intervals.

2. Hydraulic Fluid Renewal

Replace according to prescribed cycles: 2,500–3,000 operating hours.

3. Grease Lubrication

Timely replenishment minimizes component wear and ensures smooth operation.

4. Air Filter Maintenance

Clean or replace air filters regularly to,Guarantee clean air intake for engines.Enhance fuel efficiency.

5. Coolant System Check

Monitor fluid levels and maintain clear coolant circulation to prevent overheating.

6. Radiator Cleaning

Critical for heat dissipation during operation. Remove debris to sustain engine efficiency.

7. Track Tension Adjustment

Inspect and calibrate tension periodically.Maintain within standardized range to extend service life

8. Transmission System Inspection

Examine drive chains/gears routinely.Replace severely worn components immediately