SANY 25-ton Truck Crane Specification

Compact & Maneuverable Design: Overall height of merely 3.5m (below most height-restriction bars) with 11m turning radius, enabling navigation through narrow urban streets.

Versatile Applications:

- Urban viaduct component installation (boom length covers six-lane roads)

- Warehouse container handling (25-ton self-weight lifting capacity)

- Wind power equipment maintenance (jib extendable to 40.5m working height)

SANY 25-ton truck crane, manufactured in June 2021, with 2,800 km mileage and 329 operating hours. Features a 42m main boom + 8m jib configuration, intact cabin protective film, fully functional systems, maintained in near-new condition."

By Choosing us, You Gain:

A high-performance used truck crane;

Robust assurance of equipment safety and reliability;

A quality-centric partner for long-term trust;

A strategic asset investment delivering higher ROI;

We don’t sell "cheap" – we deliver enduring value proven through time and heavy-load trials.

SANY 25-ton Truck Crane Specification

Maximum Lifting Capacity: 25 tons (at 3m radius)

Fully Extended Boom: 50 meters

Load at Maximum Radius: 1.8 tons

Lifting Height: 49.5m (main boom + jib)

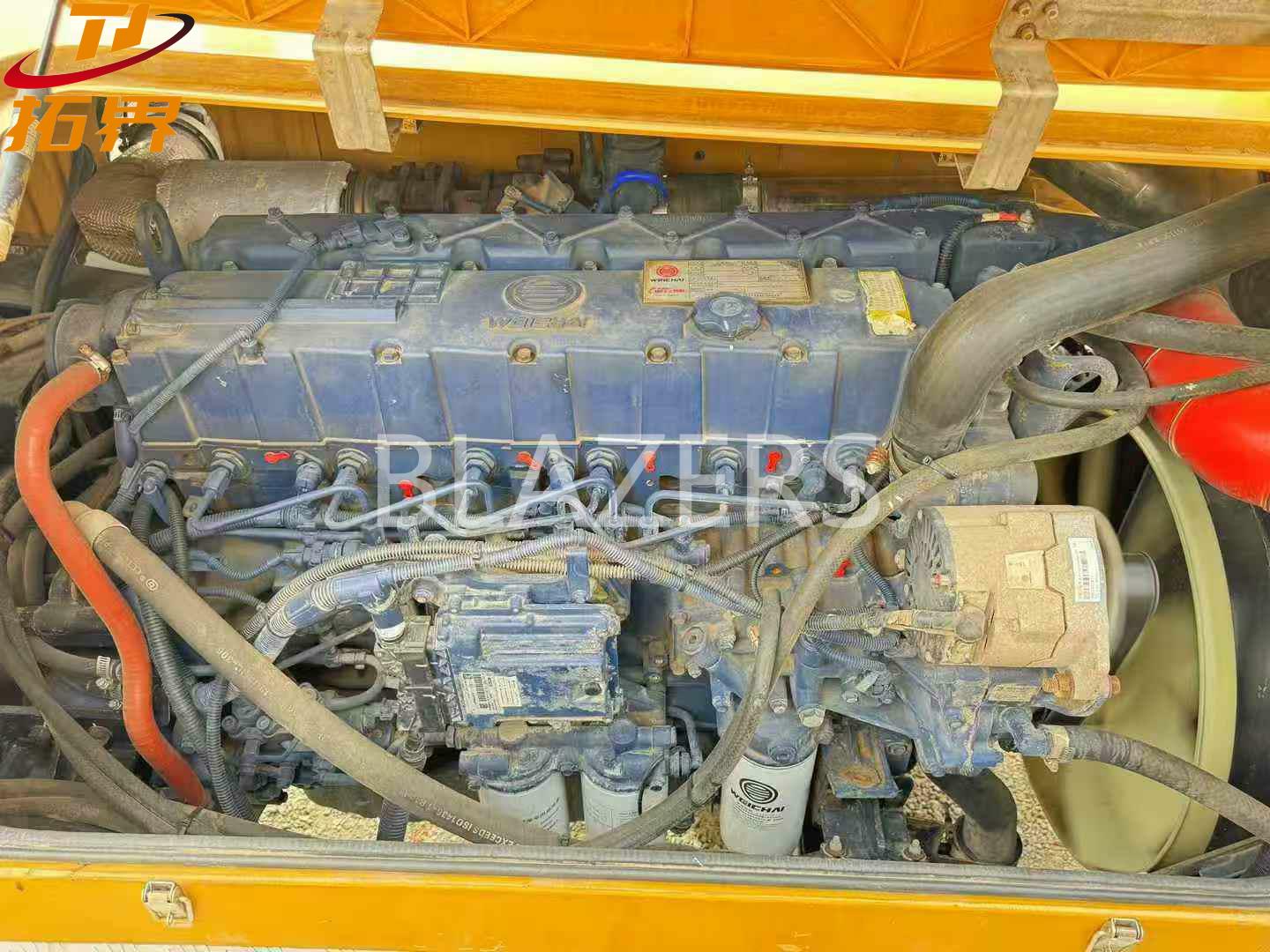

Engine Model: Weichai WP7.300E51

Power: 221kW (300 hp)

Fuel Tank Capacity: 400L

Maximum Speed: 90 km/h

Minimum Turning Radius: 11m

Gradeability: ≥40%

Dimensions & Weight: 12.9×2.5×3.5m (L×W×H)

Total Weight: 31.2 tons

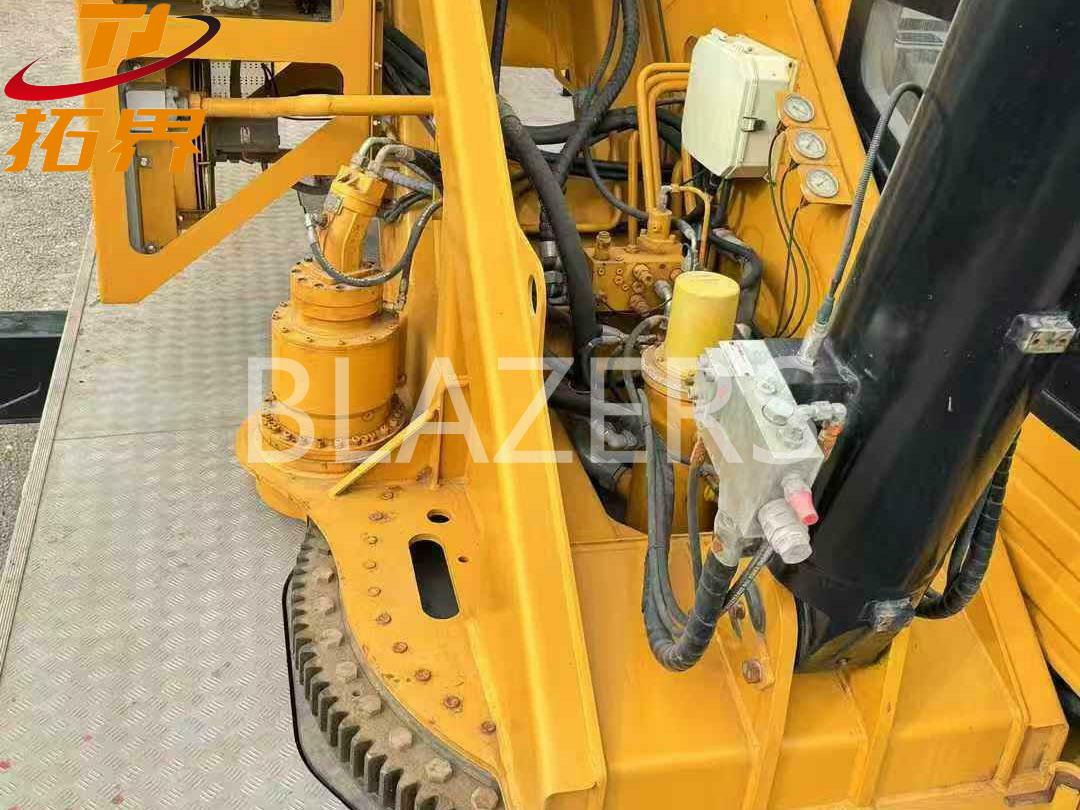

Outrigger Span: 6.1×6.5m (longitudinal×transverse)

Daily Maintenance for Truck Cranes

1. Regularly inspect tightening conditions of all fasteners, especially slewing bearing bolts.

2. Test brake assemblies of hoisting mechanisms weekly to ensure safety compliance.

3. Maintenance schedule:

- Weekly: Clean/lubricate main boom lower surfaces

- Monthly: Maintain hooks, drive shafts, wire ropes, boom pivot pins

4. Gear oil replacement: Approximately every 12 months. Monitor fluid levels and top up if low.

5. Hydraulic fluid management: Filter or replace every 6 months under normal operation.

6. Pre-operation safety checks: Verify all safety devices daily; repair faults before use.

Mandatory Replacements Before Machinery Shipment

1. Full fluid renewal: Engine oil, hydraulic fluid

2. Filter replacements: Engine oil filter, diesel filter, air filter

3. Wear-prone components: All damaged/deteriorated parts replaced with new OEM-grade components